Factory Automation

Factory Automation

This page is being translated by Google Translate

You're invited! Stay up to date with our latest company news, customer stories and job vacancies.

Read more →Dare to innovate and let logistics automation boost your competitiveness. Upgrade your production process with us and capture the benefits of scale, speed and control at lower operational costs.

We specialize in moving pallets and crates from docks to production lines and back. Our solutions match with the fast-paced demands of food processing and manufacturing. Whether products are being cut, packed or assembled: let us take care of the rest.

Delicate food products that undergo a variety of different processes need special care. In the cheese industry we helped customers to integrate and automate different processes like treatment, ripening and processing of naturally aged and film-ripened cheeses. This resulted in a very efficient and flexible process flows and reduction of the operational costs.

(Raw) meat requires a delicate handling in your intralogistics. In a temperature controlled environment (cooled or frozen), our material handling systems can be perfectly integrated. Our automated storage systems are designed for temperatures as low as -25 degrees, allowing warehouses to be operated in freezing temperatures without lights and human interaction, retrieving and delivering pallets with automated door closing significantly reducing energy loss.

Viscon is a leading partner for many companies in the industry. We can take care of the handling of punnets, bags, nets, boxes, and pallets. We have supplied many specialized solutions in grading, weighing, flowpacking, case packing, palletising and warehousing for storage of the palletized and finished products.

Due to the heavy weight, a great deal of efficiency can be gained by automating the post-harvest process. Viscon offers automation for weighing, packing, case packing and palletizing, But also automatic warehousing solutions including the integration with ventilation walls to control the temperature and humidity of the products.

The food service sector places heavy demands on logistics, particularly when it comes to supplying restaurants, catering companies and hospitals. We take care of the handling, storage and cleaning of your trolleys, roll cages, crates and pallets. With our solutions, companies in the food service sector can improve their operations, lower costs and at the same time ensure the satisfaction of their customers.

Our solutions go beyond the previously mentioned markets and can be fully designed to your needs e.g. bakery, cold storage, industry.

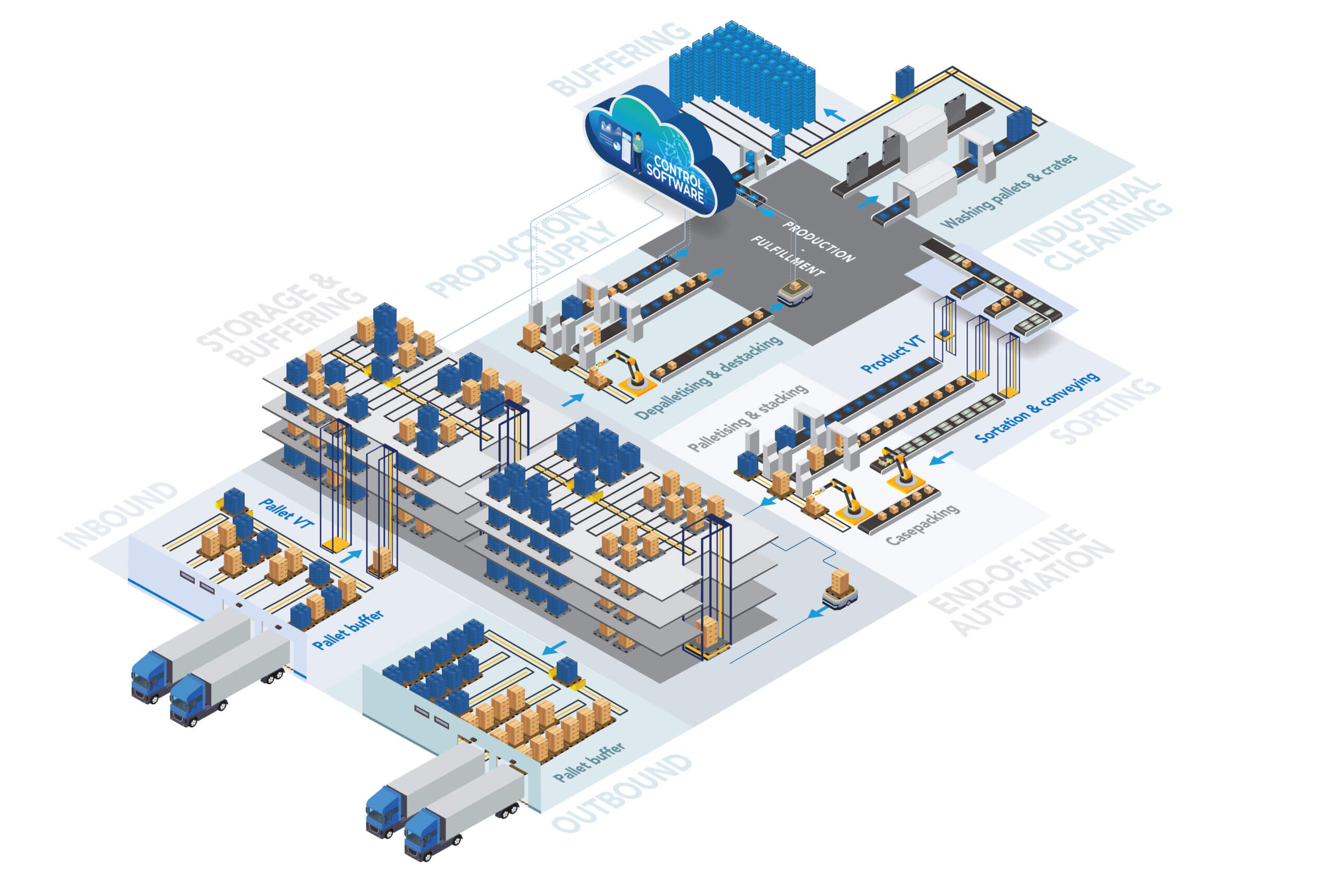

Our logistics solutions take care of the entire flow of products, crates and pallets. We make sure they are automatically moved, buffered and stored throughout the production process. In addition, our expertise in crate cleaning solutions enables you to control the flow of thousands of dirty and clean crates throughout your facility.

Our Matrix pallet shuttle warehousing system is designed as a storage buffer for producers with a high pallet throughput. This single or multi-level storage system keeps up with your most demanding peaks and provides the most compact storage.

Learn moreOur portfolio consists of configurable pallet conveyors, shuttles, lifts, palletisers and stackers. We also include crate or box conveying to create a seamless connection to your processing or packaging lines. Third-party solutions for robotics or AGVs can be integrated to create the best handling system.

Learn moreViscon provides a diverse range of handling and transportation systems in processes like conveying, (de)stacking, (un)loading, box folding, crate unfolding, sorting, order picking, storage and palletizing.

This next generation of software intelligently integrates all automation functions. It offers product traceability and unlocks performance optimization. This allows our customers to get the most out of their production facility. The software incorporates the functionality of MES, WCS and WMS and can be integrated with existing systems such as ERP.

Learn moreWe integrate all equipment and software and hand over a seamlessly working process for a new or existing production line. A flexible approach is possible thanks to our in-house engineering, production and software capabilities.

Our palletizers will be based on the requirements and needs of your production location, for example in terms of capacity and available physical space on the work floor. Our palletizers and depalletizers are applicable for a wide reange of products and pallet types to be stacked or destacked. In addition, we supply all necessary equipment, such as conveyor belts, pallet tracks and fencing.

Viscon provides belt, roller and chain conveyors for product carriers such as pallets, boxes and crates. Available in different materials such as aluminum, steel and stainless steel, as well as curved and spiral conveyors.

Examples of Viscon’s robotic applications include: pick & place systems, palletization and depalletization of various products, order picking, case packing, loading and unloading, etc.

We plug the hardware in our in-house developed intelligent software that will have the same base and structure as the rest of our system solutions. This means we can deliver a fully integrated solution, all controlled by one software system.

Designing an optimal crate flow is key when crates need to be cleaned and handled by the hundreds and thousands per hour. At Viscon, we create fully automated cleaning solutions that let you focus on your core business.

Learn moreBased on your operations, facility and preferences our engineers design the optimal logistics flow. We use standard components, which can easily be modified and scaled up. We can offer this flexibility thanks to our in-house engineering, production and software capabilities.

We take care of the total project management from concept to commissioning. It’s about the integration of equipment into a complete system. Powered by software that creates higher efficiency and performance of your facility.