Factory Automation

Factory Automation

This page is being translated by Google Translate

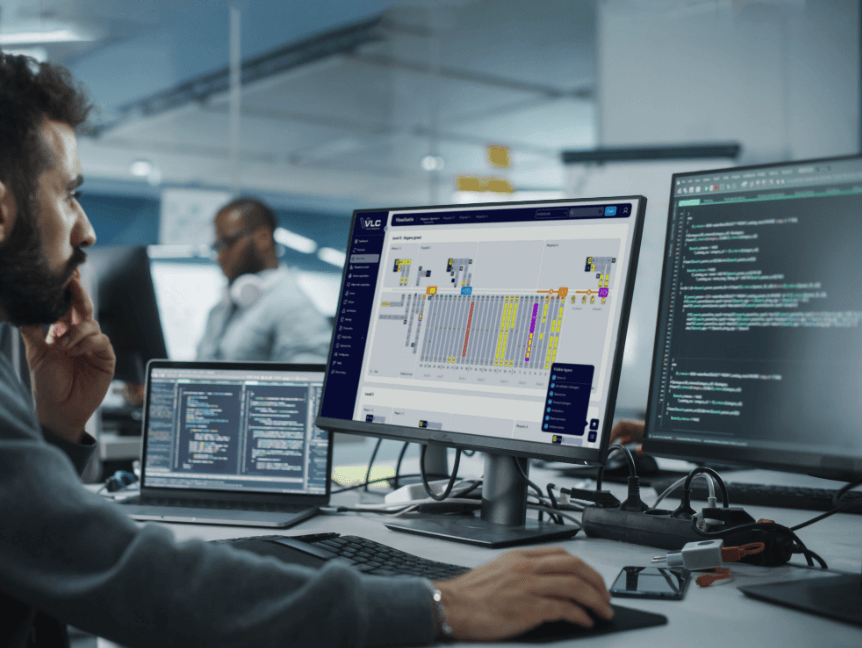

Viscon Factory Intelligence software gives you optimal control and management over your entire process. This next generation of software intelligently integrates work processes with your automation technology. It offers traceability and unlocks performance optimization. This allows our customers to get the most out of their automated warehouse, logistics center or production facility.

The software incorporates the functionality of MES, WCS and WMS. We integrate with existing software systems. By linking to an overarching ERP system we unlock the benefits of information exchange.

Our software excels with an user-friendly interface, quick learning curve, and optimized control for complex automation systems, enhanced by rich visualizations, making it easy to use.

We use standard software components, which can easily be modified and scaled up. Our goal is to create a costeffective, tailored solution that efficiently aligns with your unique production process.

Compatible with diverse overarching software systems (ERP, WMS, MES), and automation equipment from various suppliers. Proven systems in a wide range of industries.

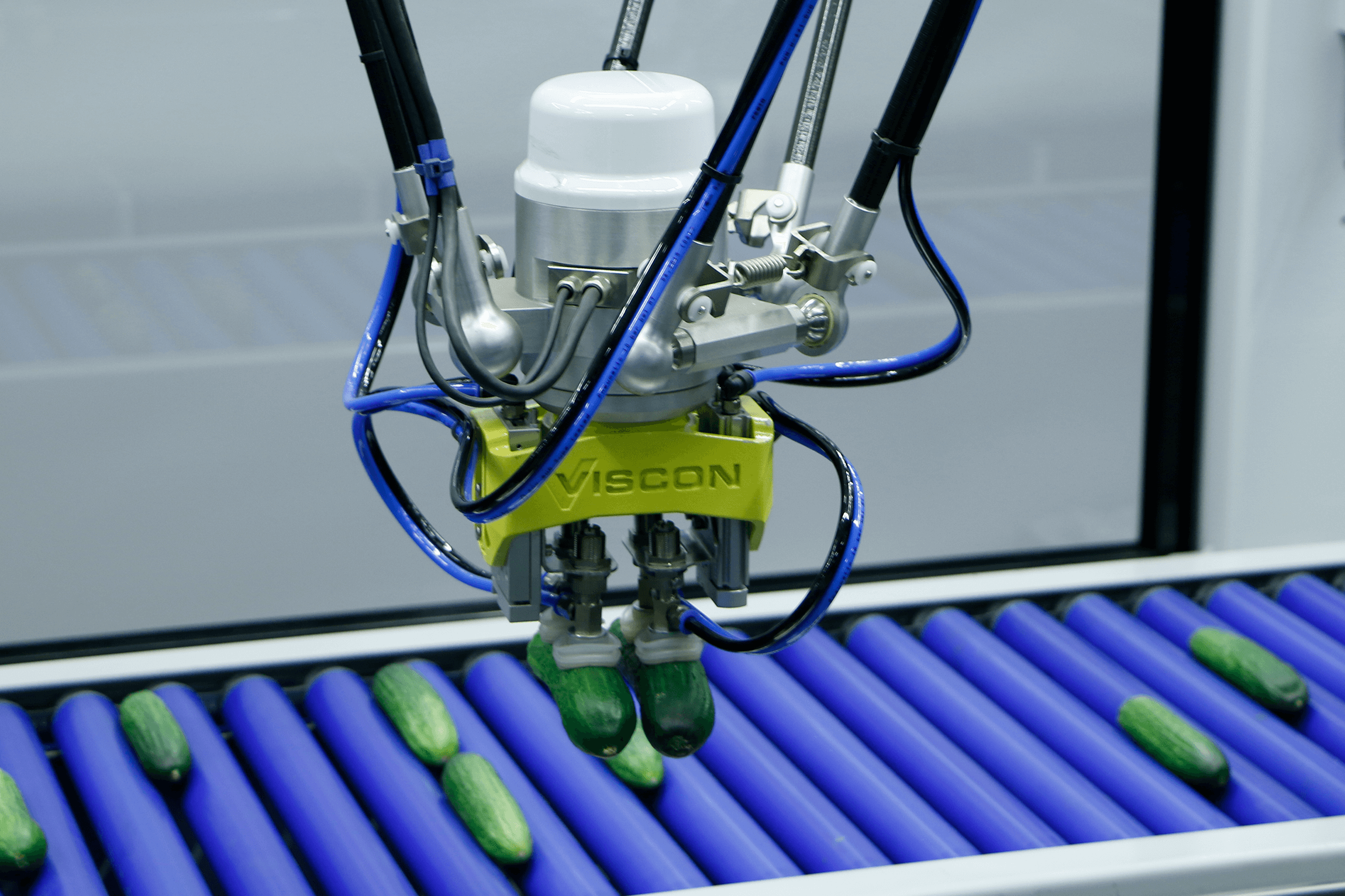

Tailored to demanding needs, we can provide customizable software and develop a hardware solution to integrate into your production process. Elevate your operations, increase efficiency, and achieve consistent product excellence with our AI Vision Solution.

VFI software provides all the required functionalities to manage your product handling processes. All your punnets, boxes, and pallets can be traced and managed in the system.

At Viscon Group, we are passionate about production processes and the limitless possibilities technology has to offer. We provide machine automation, software and integrated solutions to make your processes more sustainably profitable, scalable and easy. As a system integrator, we build machines but moreover we build integrations. Our software platform is paramount in this. This allows our customers to get the most out of their automated warehouse, logistics center or production facility.

Viscon Factory Intelligence, an integral part of Viscon Group, is our in-house IT software company that enables us to provide customers with all the necessary software for optimal control and management of the entire logistical process. Expertise in hardware and software strengthens our value as a software integrator and allows for a customer centric design approach.