Factory Automation

Factory Automation

This page is being translated by Google Translate

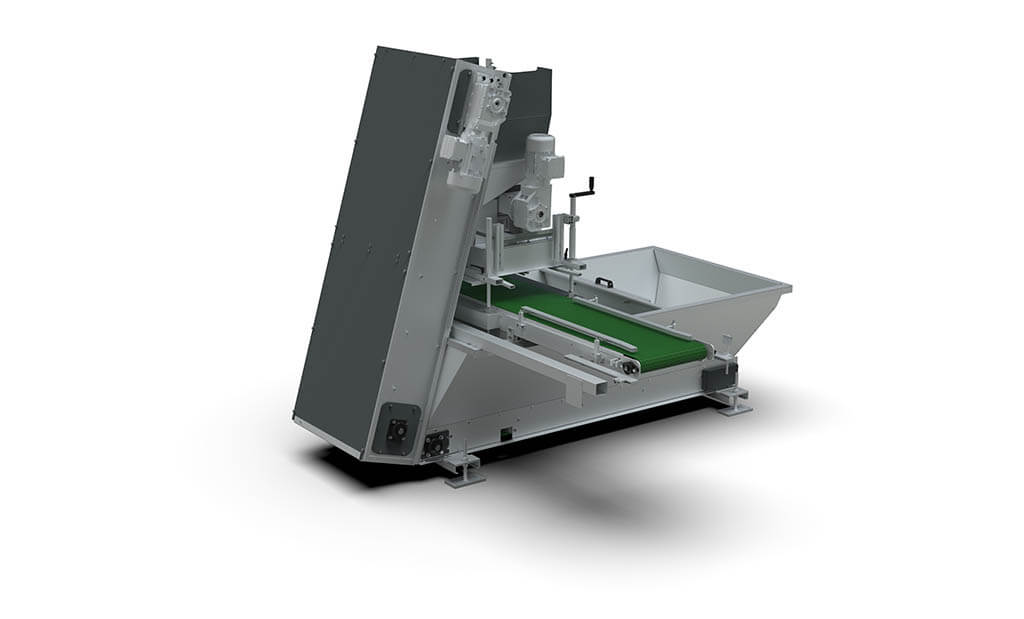

The Twin filler is a filling machine for filling trays, flats, and packs. It provides high-capacity filling using a double twin-rotor. The filler is fully adjustable for different tray dimensions and filling densities. The Twin filler is standard equipped with a soil recycling system.

The Twin Filler is a high-capacity compact tray filler for trays, flats, and packs. It is suitable for trays with maximum dimensions W x H = 400 x 210 mm. The max. length of the tray is variable (max length of belt).

The Twin Filler contains a filling head that is equipped with two rotors. This ensures an excellent and high-speed filling result. The speed of the rotors is adjustable by a frequency controller to guarantee the optimal filling density. After filling, the trays are brushed for a clean and uniform result.

The soil is transported from the hopper to the soil elevator using a belt conveyor. The speed of the belt is adjustable for an equal supply of soil. The excess soil is returned to the hopper for reuse. The hopper has a content of 1000 liter.