This page is being translated by Google Translate

The pallet shuttle system maximizes storage by moving pallets to deep storage lanes on each level using satellites. This type of ASRS system is ideal for high-throughput operations that need reliable 24/7 performance. It offers superior capacity and storage density compared to alternative systems.

The pallet shuttle system is designed to revolutionize your warehouse operations by delivering unmatched storage density and efficiency. This advanced solution minimizes the need for aisles, allowing for optimal use of space while maximizing storage capacity. The shuttle system is ideal for high-throughput environments. The pallet shuttle excels in handling large volumes with precision and speed, ensuring seamless operations even during peak times.

Do you want more information about our pallet shuttle system and the different options? Download our free brochure and read more about:

Stores and handles pallets and similar unit loads, such as pallet boxes, bins, racks, gitter boxes and tray systems. It is also suitable for non-standard unit load. For example, if you have cheese racks or large crates of onions

This single or multi-level shuttle system keeps up with your most demanding peaks and offers the highest storage density. This system also allows you to be 70% more space-efficient than traditional warehouses.

Our automated storage and retrieval solutions are designed to operate in -30°C to +40°C. Thanks to its charging technology Matrix can be operated in cooling and freezing conditions.

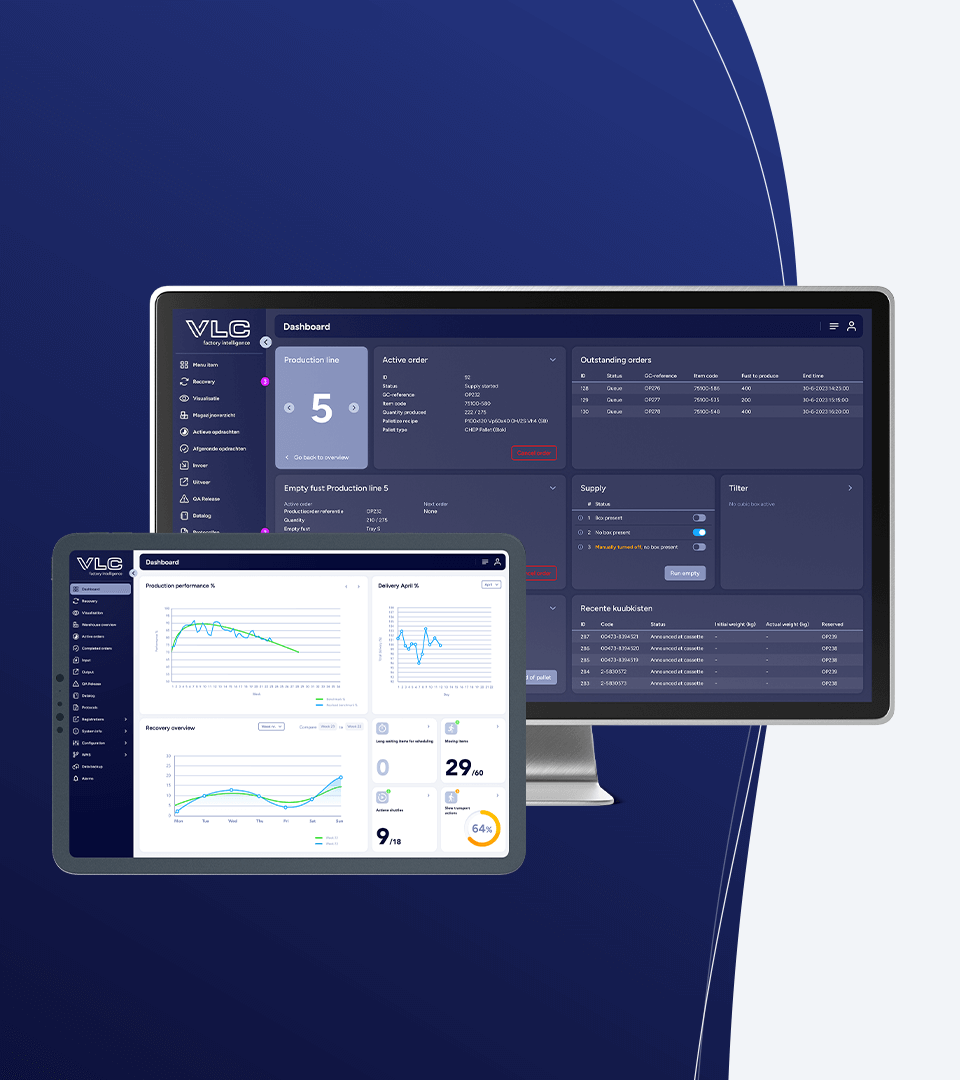

With our intelligent software you gain full visibility of your inventory. Next to that our software can be directly integrated with an ERP system removing the need for additional WMS software reducing costs and complexity.

Automation reduces damaged pallets or boxes, as there are no longer manual handling operations. This also saves on labor costs and forklift maintenance, further reducing operational expenses.

We design and manufacture 95% of our equipment in-house, allowing us to engineer tailored solutions. Moreover, 3rd party equipment can be easily integrated into our total solution.

The Omnishuttle is specially designed for high-density storage systems by offering unmatched flexibility and operational efficiency. Unlike traditional systems, the Omnishuttle combines the capabilities of both a shuttle and a satellite into a single integrated solution. This allows the Omnishuttle to move effortlessly across multiple levels and multiple directions.

Viscon is a trusted partner in a wide range of industries, including fruit and vegetables, cheese and dairy, and meat and poultry. Our extensive experience and deep understanding of these sectors allow us to address the unique challenges and requirements of your business. Below, you’ll find success stories showcasing our track record in delivering efficient pallet shuttle solutions tailored to the specific needs of each industry. Let us help you optimize your logistics with expertise you can rely on.

At Viscon, we deliver complete intralogistics solutions that go beyond automated storage and retrieval systems. From palletizing and depalletizing to seamless integration into your existing processes, we provide end-to-end solutions tailored to your needs. Our proprietary VLC software suite offers advanced functionalities, including material flow control, production management, track-and-trace capabilities, and AI vision technology. With full integration services and unmatched flexibility, Viscon ensures your entire logistics chain operates efficiently and future-proof, setting us apart from the competition.