This page is being translated by Google Translate

Automated palletising and depalletising are essential steps in modern end-of-line logistics. At Viscon, we design smart, scalable systems that streamline the loading and unloading of pallets with precision and speed. Whether you’re handling food or non-food products, our solutions ensure consistent stacking, secure transport, and seamless integration with your internal logistics. From robotic palletisers to advanced depalletising units, we offer tailor-made automation that fits your production flow and boosts operational efficiency.

At Viscon, we combine in-depth knowledge of internal logistics with innovative technology to automate (de)palletising processes. Our expertise enables us to develop solutions that are not only efficient, but also scalable, safe, and fully integrated into broader production environments. We understand that every customer has unique requirements for end-of-line automation, which is why we deliver tailor-made systems that align perfectly with operational goals.

Viscon’s process expertise is deeply rooted in the food and agro industries, where hygiene, throughput, and product integrity are critical. We understand the unique challenges of handling perishable goods, bulk flows, and high-frequency logistics in environments that demand both precision and flexibility.

We engineer flows that reduce manual labor, maintain cold chain integrity, and ensure traceability across the entire logistics process. Whether you’re managing fresh produce, dairy crates, meat containers, or horticultural trays, Viscon’s process knowledge ensures that your internal logistics are hygienic, efficient, and ready to scale.

Viscon excels at connecting machines, software, and data into one intelligent logistics ecosystem. In crate and box handling, this means more than just moving goods. It’s about orchestrating every step of the process.

We integrate conveyors, lifts, palletisers, washers, and inspection systems with control software and ERP/WMS platforms to ensure seamless coordination, full traceability, and centralized control. Our system integration expertise enables real-time decision-making, efficient flow control, and scalable automation across departments and production zones.

In food and agro environments, hygiene is not optional, it’s essential. Viscon designs crate and box handling systems that meet the highest standards for cleanliness, safety, and compliance.

Our stainless steel machines are built for easy cleaning, minimal downtime, and long-term durability in cold, wet, or high-throughput conditions. Whether you’re handling dairy crates, meat containers, or horticultural trays, our hygienic designs ensure your logistics meet HACCP, GMP, and industry-specific protocols without compromising on performance.

Automation is only as powerful as the software behind it. Viscon’s proprietary Warehouse Control System (WCS) provides real-time insights and control over your entire logistics flow. It connects all crate and box handling modules, from conveyors and lifts to palletisers and washers, into one centralized platform.

The WCS enables full track & trace, live KPI dashboards, and seamless integration with ERP, WMS, and MES systems. With software intelligence at the core, you gain visibility, flexibility, and control to optimize operations and scale with confidence.

No two production environments are the same and Viscon’s solutions are built to reflect that. Our crate and box handling systems are modular by design, allowing you to start small and expand as your business grows.

Whether you need a single crate washer or a fully automated warehouse flow, our systems adapt to your layout, product types, and operational goals. We engineer for flexibility, so you can respond to changing market demands, seasonal peaks, and long-term growth without rethinking your entire setup.

At Viscon, we believe that successful automation starts with a well-thought-out approach. Our working method is structured, transparent, and always tailored to the customer. We guide each project from concept to implementation, with attention to technology, process, and communication.

We begin with a thorough assessment of the logistical challenge. Together with the customer, we map out the current situation and define the desired goals. Based on this, we advise on the optimal configuration of pallet lifters and any additional systems.

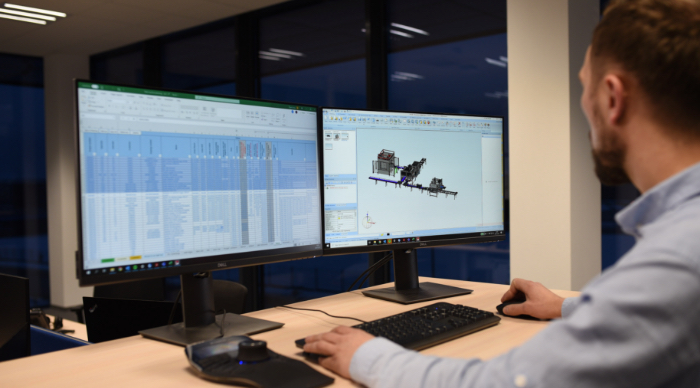

Using the analysis as a foundation, we develop a technical concept that aligns with operational objectives. We visualize the solution through layouts, simulations, or 3D models, and coordinate the concept with all relevant departments—from engineering to operations.

Our engineers design robust and safe systems tailored to the environment and product type. We ensure efficient on-site installation with minimal disruption to existing processes. Safety, ease of maintenance, and scalability are key priorities.

We connect the pallet lifters to warehouse control software and ERP systems. This enables real-time insights, automated control, and seamless communication between systems. We also offer integration with AGVs, AMRs, and other automation solutions.

After installation, we conduct a careful handover including functional tests and quality checks. We train operators, technical staff, and IT teams in the use and management of the systems. Customized documentation and manuals are provided.

Even after delivery, we remain involved through monitoring, service, and updates. We analyze performance and advise on optimizations or future expansions. Our support team is available for technical questions and maintenance. support to ensure long-term optimization and adaptability.