This page is being translated by Google Translate

Viscon’s pallet lift solutions are designed to automate the vertical movement of pallets between different levels within industrial and warehouse environments. Whether transferring pallets between production zones or storage layers, our systems offer a space-saving, and scalable solution for internal logistics. Compatible with conveyors, ASRS systems, and other automation technologies, Viscon pallet lifters ensure a smooth flow of goods, reduced manual handling, and optimal integration within your logistics process.

At Viscon, we believe in optimizing intralogistics processes with smart, scalable solutions. Our pallet lifters are designed for food processors, logistics service providers, and cold chain specialists who aim for maximum efficiency, minimal labor costs, and optimal use of warehouse space. Thanks to integrated hardware and software, we deliver customized solutions that seamlessly connect with existing processes and ERP systems. Our expertise ranges from standard pallet handling to advanced Vertical Transporter solutions with multi-level configurations, multiple in- and outfeeds, and compatibility with various pallet formats.

At Viscon, we combine technical expertise with hands-on experience to optimize intralogistics processes. Our solutions within the pallet lifter expertise block are designed for maximum efficiency, safety, and scalability:

Our VT lifters are the standard for vertical pallet movement. They are used in automated warehouses and distribution centers, enabling efficient use of space and reducing labor costs.

Automated Storage & Retrieval Systems (ASRS) allow for the automatic storage and retrieval of pallets and crates. These systems are ideal for both chilled and dry storage environments and provide a solid foundation for scalable logistics.

By integrating pallet lifters with autonomous vehicles such as AGVs and AMRs, we enable fully automated internal logistics. This increases flexibility and reduces reliance on manual labor.

Our palletizing machines, such as the Callisto, automatically load pallets with boxes or crates. Combined with VT lifters, they offer a complete palletizing solution.

These systems are often integrated with pallet lifters and include industrial washing installations and sorting systems for crates. They contribute to streamlined and hygienic processing.

At Viscon, we believe that successful automation starts with a well-thought-out approach. Our working method is structured, transparent, and always tailored to the customer. We guide each project from concept to implementation, with attention to technology, process, and communication.

We begin with a thorough assessment of the logistical challenge. Together with the customer, we map out the current situation and define the desired goals. Based on this, we advise on the optimal configuration of pallet lifters and any additional systems.

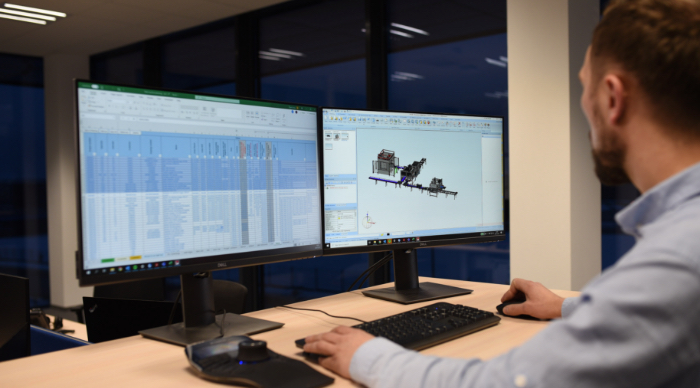

Using the analysis as a foundation, we develop a technical concept that aligns with operational objectives. We visualize the solution through layouts, simulations, or 3D models, and coordinate the concept with all relevant departments—from engineering to operations.

Our engineers design robust and safe systems tailored to the environment and product type. We ensure efficient on-site installation with minimal disruption to existing processes. Safety, ease of maintenance, and scalability are key priorities.

We connect the pallet lifters to warehouse control software and ERP systems. This enables real-time insights, automated control, and seamless communication between systems. We also offer integration with AGVs, AMRs, and other automation solutions.

After installation, we conduct a careful handover including functional tests and quality checks. We train operators, technical staff, and IT teams in the use and management of the systems. Customized documentation and manuals are provided.

Even after delivery, we remain involved through monitoring, service, and updates. We analyze performance and advise on optimizations or future expansions. Our support team is available for technical questions and maintenance. support to ensure long-term optimization and adaptability.