This page is being translated by Google Translate

Viscon’s crate & box handling solutions automate every step of your internal logistics, from destacking and washing to palletising and wrapping. Designed for high-throughput environments in food, horticulture, and industrial production, our systems ensure hygienic, efficient, and traceable handling of crates, boxes, and pallets. Whether you need a standalone module or a fully integrated logistics flow, Viscon delivers scalable automation that grows with your business.

Viscon’s expertise goes beyond engineering. We understand the logistical challenges of production environments in food, agro, pharma, and industrial sectors. Our strength lies in:

Viscon’s process expertise is deeply rooted in the food and agro industries, where hygiene, throughput, and product integrity are critical. We understand the unique challenges of handling perishable goods, bulk flows, and high-frequency logistics in environments that demand both precision and flexibility.

We engineer flows that reduce manual labor, maintain cold chain integrity, and ensure traceability across the entire logistics process. Whether you’re managing fresh produce, dairy crates, meat containers, or horticultural trays, Viscon’s process knowledge ensures that your internal logistics are hygienic, efficient, and ready to scale.

Viscon excels at connecting machines, software, and data into one intelligent logistics ecosystem. In crate and box handling, this means more than just moving goods. It’s about orchestrating every step of the process.

We integrate conveyors, lifts, palletisers, washers, and inspection systems with control software and ERP/WMS platforms to ensure seamless coordination, full traceability, and centralized control. Our system integration expertise enables real-time decision-making, efficient flow control, and scalable automation across departments and production zones.

In food and agro environments, hygiene is not optional, it’s essential. Viscon designs crate and box handling systems that meet the highest standards for cleanliness, safety, and compliance.

Our stainless steel machines are built for easy cleaning, minimal downtime, and long-term durability in cold, wet, or high-throughput conditions. Whether you’re handling dairy crates, meat containers, or horticultural trays, our hygienic designs ensure your logistics meet HACCP, GMP, and industry-specific protocols without compromising on performance.

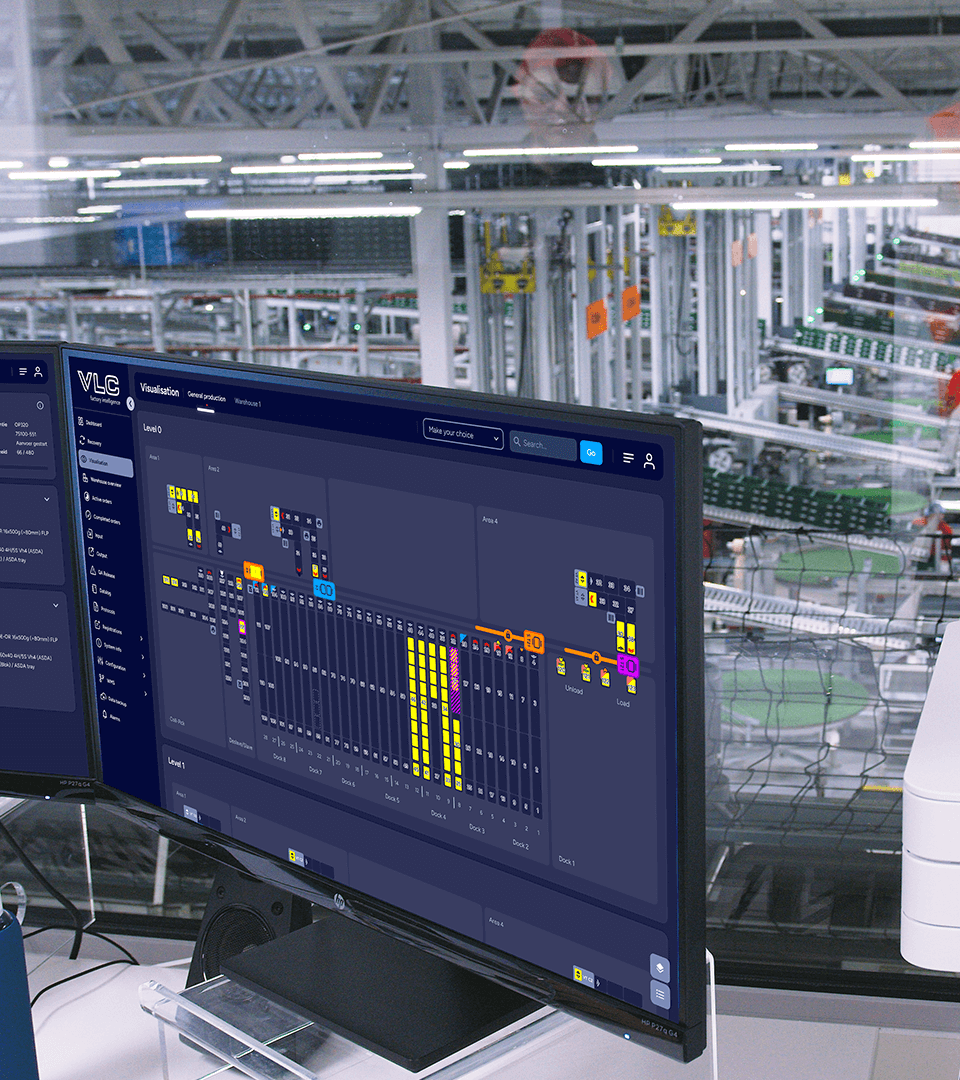

Automation is only as powerful as the software behind it. Viscon’s proprietary Warehouse Control System (WCS) provides real-time insights and control over your entire logistics flow. It connects all crate and box handling modules, from conveyors and lifts to palletisers and washers, into one centralized platform.

The WCS enables full track & trace, live KPI dashboards, and seamless integration with ERP, WMS, and MES systems. With software intelligence at the core, you gain visibility, flexibility, and control to optimize operations and scale with confidence.

No two production environments are the same and Viscon’s solutions are built to reflect that. Our crate and box handling systems are modular by design, allowing you to start small and expand as your business grows.

Whether you need a single crate washer or a fully automated warehouse flow, our systems adapt to your layout, product types, and operational goals. We engineer for flexibility, so you can respond to changing market demands, seasonal peaks, and long-term growth without rethinking your entire setup.

At Viscon, we combine decades of experience with a consultative, modular approach to automate crate and box handling across industries. Whether you’re optimizing a single process or building a fully integrated logistics flow, our solutions are engineered to deliver measurable impact.

We design crate and box handling modules that fit your facility layout and operational goals. From destacking and washing to palletising and wrapping, each unit is built for seamless integration and future scalability.

Every solution is developed in-house and tailored to your production flow, hygiene standards, and throughput requirements. We don’t offer off-the-shelf systems, we build automation that works for your business.

Our proprietary Warehouse Control System (WCS) connects all automation modules into one intelligent network. It enables real-time monitoring, full traceability, and flow control based on live data. The system integrates with ERP, WMS, and MES platforms for complete visibility.

For food, agro, and pharma environments, we offer stainless steel designs that meet strict hygiene protocols. Our systems are built for easy cleaning, minimal downtime, and compliance with industry standards.

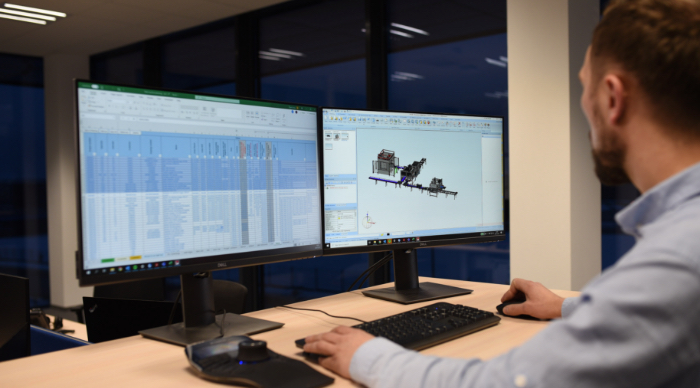

We simulate entire crate-handling lines using Emulate3D, allowing us to test performance, flow, and capacity before physical installation—saving time and reducing risk.

Our process starts with a deep analysis of your production flow, followed by KPI definition, system design, implementation, and training. We provide lifecycle support to ensure long-term optimization and adaptability.