This page is being translated by Google Translate

Dare to innovate and let logistics automation boost your competitiveness. Upgrade your production process with us and capture the benefits of scale, speed and control at lower operational costs.

We specialize in moving pallets and crates from docks to production lines and back. Our solutions match with the fast-paced demands of food processing and manufacturing. Whether products are being cut, packed or assembled: let us take care of the rest.

We supply both pallet handling and crate cleaning solutions in a variety of food processing sectors such as bakery, meat, fruit & vegetables, convenience and cheese.

Create a storage buffer to manage large volumes of incoming and outgoing pallets or introduce an automated infeed solution for your assembly line.

Our intralogistics solutions are also deployed in similar high-volume processes in industries such as beverages, non-durables and pharma.

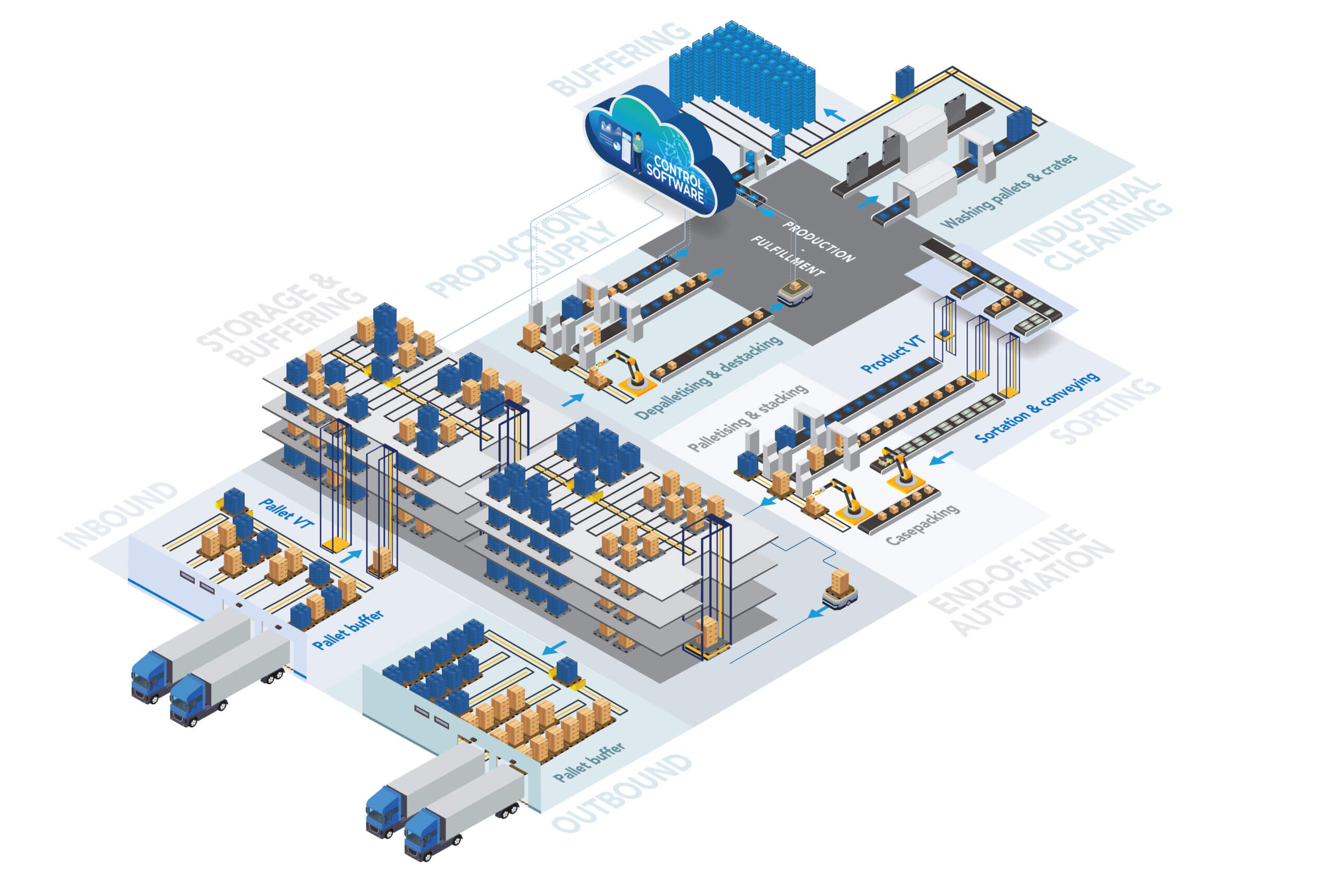

Our logistics solutions take care of the entire flow of products, crates and pallets. We make sure they are automatically moved, buffered and stored throughout the production process. In addition, our expertise in crate cleaning solutions enables you to control the flow of thousands of dirty and clean crates throughout your facility.

Based on your operations, facility and preferences our engineers design the optimal logistics flow. We use standard components, which can easily be modified and scaled up. We can offer this flexibility thanks to our in-house engineering, production and software capabilities.

We take care of the total project management from concept to commissioning. It’s about the integration of equipment into a complete system. Powered by software that creates higher efficiency and performance of your facility.

This next generation of software intelligently integrates all automation functions. It offers product traceability and unlocks performance optimization. This allows our customers to get the most out of their production facility. The software incorporates the functionality of MES, WCS and WMS and can be integrated with existing systems such as ERP.

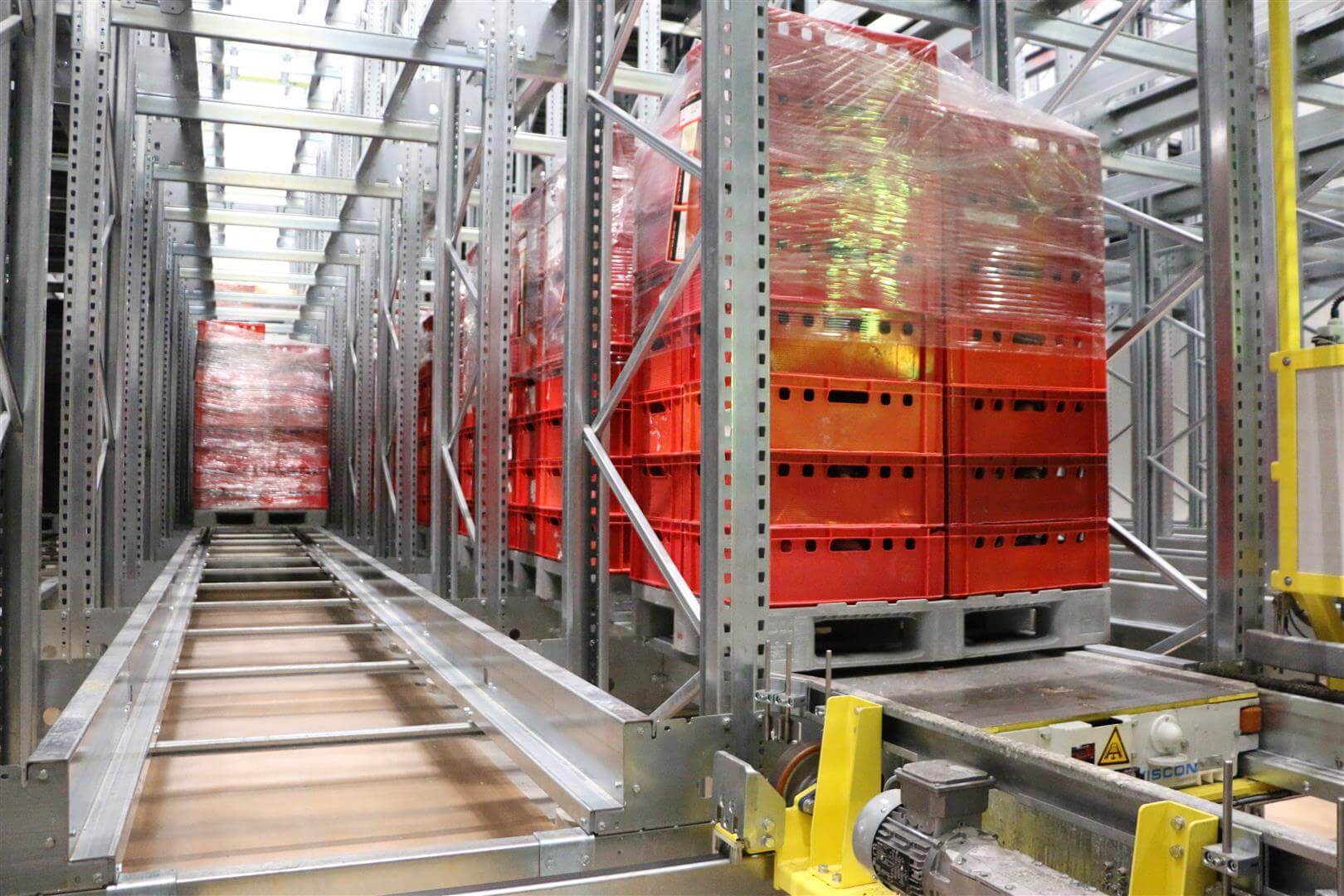

Learn moreOur Matrix pallet shuttle warehousing system is designed as a storage buffer for producers with a high pallet throughput. This single or multi-level storage system keeps up with your most demanding peaks and provides the most compact storage.

Learn moreOur portfolio consists of configurable pallet conveyors, shuttles, lifts, palletisers and stackers. We also include crate or box conveying to create a seamless connection to your processing or packaging lines. Third-party solutions for robotics or AGVs can be integrated to create the best handling system.

Learn moreDesigning an optimal crate flow is key when crates need to be cleaned and handled by the hundreds and thousands per hour. At Viscon, we create fully automated cleaning solutions that let you focus on your core business.

Learn moreViscon provides a diverse range of handling and transportation systems in processes like conveying, (de)stacking, (un)loading, box folding, crate unfolding, sorting, order picking, storage and palletizing.

Examples of Viscon’s robotic applications include: pick & place systems, palletization and depalletization of various products, order picking, case packing, loading and unloading, etc.

We plug the hardware in our in-house developed intelligent software that will have the same base and structure as the rest of our system solutions. This means we can deliver a fully integrated solution, all controlled by one software system.

Viscon provides belt, roller and chain conveyors for product carriers such as pallets, boxes and crates. Available in different materials such as aluminum, steel and stainless steel, as well as curved and spiral conveyors.