Factory Automation

Factory Automation

This page is being translated by Google Translate

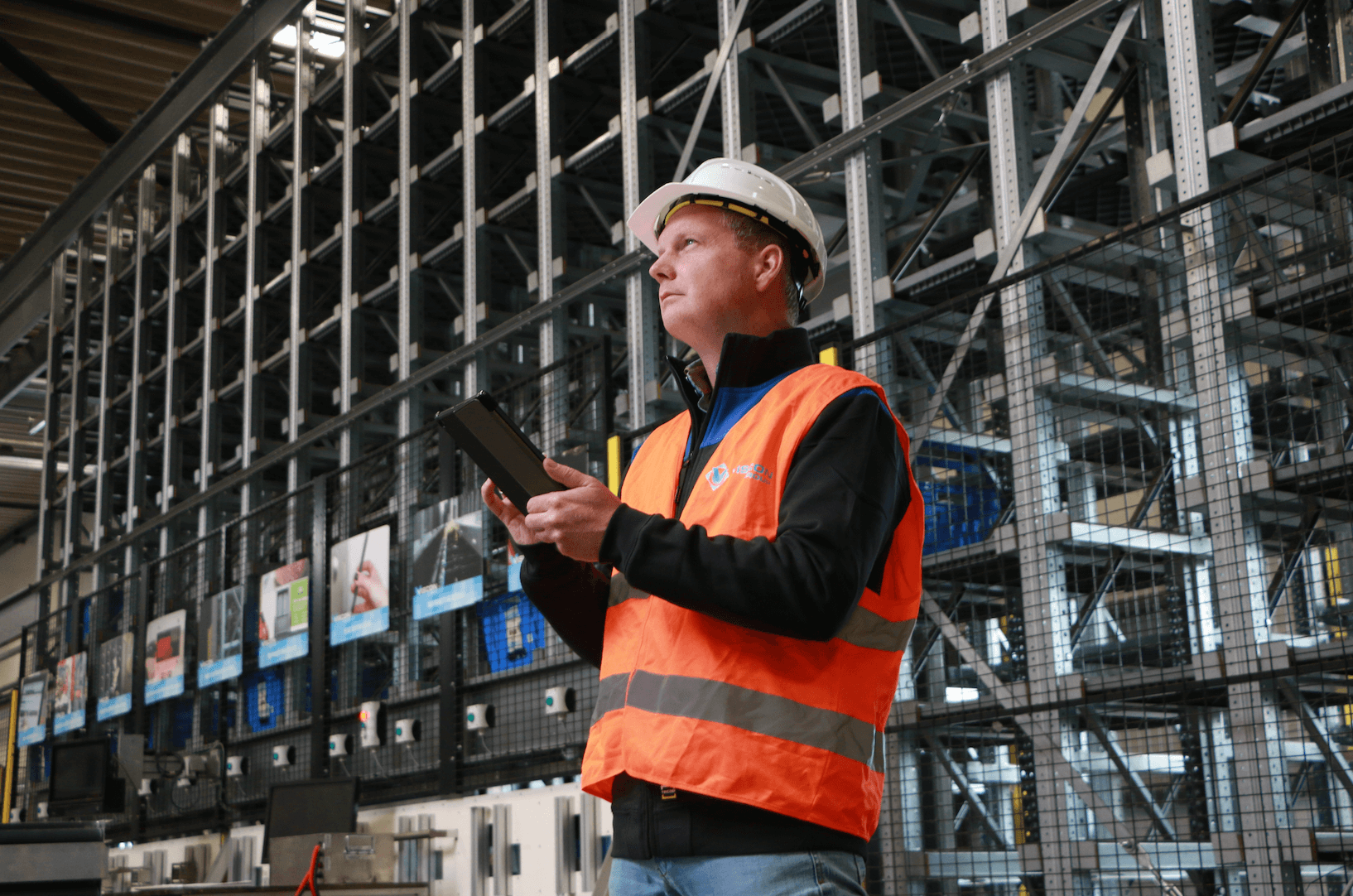

Veilig werken met machines is essentieel om ongelukken op de werkvloer te voorkomen en het werkplezier van uw medewerkers te vergroten.

Als fabrikant van een groot aantal uiteenlopende automatiseringsprojecten kan Viscon u helpen de veiligheid van uw bestaande machinepark te verbeteren. Onze ervaren Machine Safety Experts onderscheiden zich met hun technische kennis en praktische vertaalslag in de begeleiding en realisatie van veiligheidsaanpassingen.

Bent u op zoek naar ondersteuning op het gebied van machineveiligheid? Neem dan contact op met onze adviseurs voor een vrijblijvend adviesbezoek.

Machines hebben vaak afschermingen zoals kappen of hekwerken om toegang tot bewegende delen te voorkomen. Helaas worden deze soms verwijderd voor tijdelijke werkzaamheden en niet teruggeplaatst, of raken uiteindelijk zelfs kwijt. Zorg er daarom voor dat de afschermingen in orde zijn. We kunnen ze voor u herstellen of veilige alternatieven bespreken als u de afschermingen minder praktisch vindt.

Zorg voor goed functionerende veiligheidsvoorzieningen en controleer deze regelmatig. De praktijk wijst helaas uit dat deze soms buiten werking worden gesteld of anderszins worden gemanipuleerd. Vaak met de beste bedoelingen van de werknemers om de productie zo weinig mogelijk te verstoren. Als u problemen constateert, ga dan in gesprek met de werknemers om de oorzaak te achterhalen en zoek samen naar praktische oplossingen. Wij kunnen u hierbij ondersteunen en adviseren over praktische veiligheidsoplossingen.

Onveilige omgang met machines komt vaak voor door personeelswisselingen, veranderende omstandigheden of verlies van handleidingen. Als machineontwerpers kunnen wij u adviseren over het trainen van uw personeel en het aanpassen van machines indien nodig. Uiteraard kunt u dit ook zelf doen door heldere procedures op te stellen en toe te zien op het juiste gebruik van de machines.

Grote, onoverzichtelijke werkingsgebieden kunnen leiden tot onveilig gebruik van machines. Zeker bij een hoge productiedruk willen medewerkers wel eens een machine opstarten zonder dat zij weten dat een collega zich in een werkingsgebied bevindt. Om een beter overzicht te creëren kunt u bijvoorbeeld spiegels of bordessen plaatsen en heldere werkprocedures opstellen. Ook hier kunnen wij u adviseren over allerlei vormen van maatregelen tegen het onverwachts opstarten van machinelijnen.

Is uw productielijn door de jaren heen uitgebreid, of heeft u andere looproutes gekregen in uw bedrijf? Dan kan het voorkomen dat machines niet goed meer bereikbaar zijn voor interventies, schoonmaken of onderhoud. U kunt hiervoor werkplannen opstellen waarbij wellicht gebruik gemaakt moet worden van steigers, hoogwerkers of trappen en bordessen, maar ook wij kunnen u adviseren over veilige toegangsmogelijkheden, zoals het scheiden van werkingsgebieden. Dit kan zelfs uw productiecapaciteit verhogen.

Bent u opzoek naar ondersteuning met betrekking tot machineveiligheid? Neem contact op met onze adviseur voor een vrijblijvend adviesbezoek en een analyse van de veiligheidsmaatregelen binnen uw machinepark.