This page is being translated by Google Translate

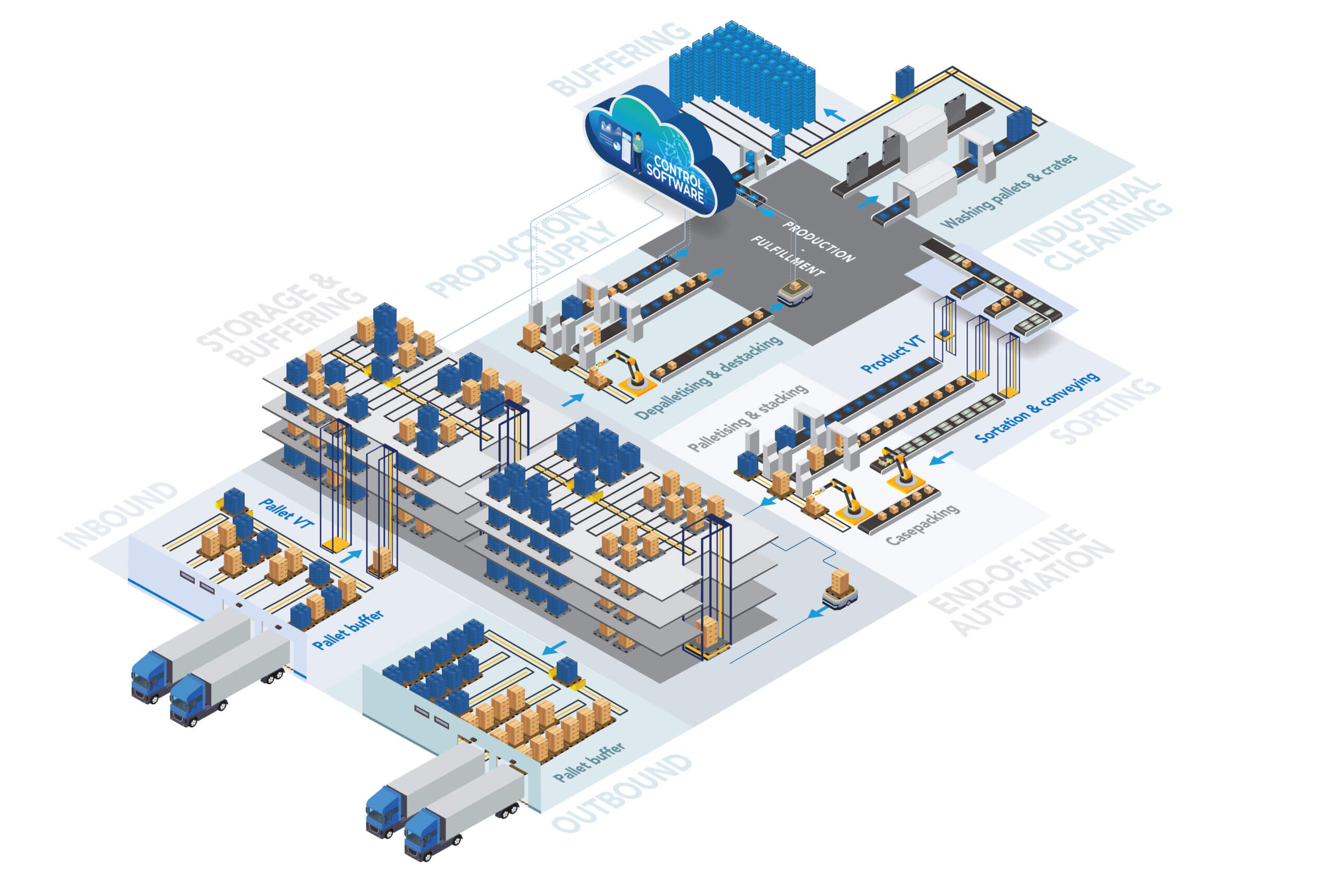

Viscon Warehouse Automation ist auf die Entwicklung praktischer und innovativer Lösungen für Hochdichte-Lagersysteme und die Handhabung von Produktträgern in Prozessen wie Sortier-, Kommissionier-, Palettier- und industriellen Waschlinien spezialisiert, sowohl in Lebensmittel- als auch in Nicht-Lebensmittelumgebungen. So können wir schlüsselfertige Projekte jeder Größe konstruieren, produzieren und realisieren. Zahlreiche Projekte mit einzigartigem Entwurf und Referenzen in vielen verschiedenen Sektoren sind der Beweis für die herausragende Position von Viscon Warehouse Automation auf dem Markt.

Wagen Sie Innovation und steigern Sie Ihre Wettbewerbsfähigkeit mit unserer Automatisierung. Verbessern Sie Ihren Produktionsprozess mit uns und nutzen Sie die Vorteile von Skalierung, Geschwindigkeit und Kontrolle bei geringeren Betriebskosten.

Viscon liefert automatisierte Lager- und Abrufsysteme (ASRS) für Lagerhäuser, Vertriebszentren und Produktionseinrichtungen. Dank des Einsatzes technisch ausgereifter Module sind wir in der Lage, Lösungen zu bieten, die sich problemlos an jedes Gebäude anpassen oder sich in jede logistische Herausforderung integrieren lassen. Für die automatisierte Palettenlagerung bietet Viscon zwei Lösungen: Eine, die mit Shuttle-Satelliten arbeitet, oder eine multidirektionale, mehrstöckige OmniShuttle-Lösung.

Mit über 60 Jahren Erfahrung und einem starken Fokus auf Innovation bieten wir maßgeschneiderte Lösungen, die perfekt auf Ihre spezifischen Bedürfnisse abgestimmt sind.

Optimieren Sie Ihre Logistikprozesse und senken Sie Betriebskosten ohne Abstriche bei der Qualität.

Wir wissen ganz genau, dass jedes Unternehmen einzigartig ist. Deshalb bieten wir flexible Lösungen, die auf Ihre Anforderungen und Ziele zugeschnitten sind.

The OmniShuttle is Viscon’s latest innovation, specifically designed for high-density storage systems by offering unmatched flexibility and operational efficiency. Unlike traditional systems, the OmniShuttle combines the capabilities of both a shuttle and a satellite into a single, integrated solution. This hybrid functionality allows the OmniShuttle to move effortlessly across multiple levels, as well as in multiple directions, both horizontally and vertically.

Learn moreOur Matrix pallet shuttle warehousing system is designed as a storage buffer for producers with a high pallet throughput. This single or multi-level storage system keeps up with your most demanding peaks and provides the most compact storage.

Learn moreOur portfolio consists of configurable pallet conveyors, shuttles, lifts, palletisers and stackers. We also include crate or box conveying to create a seamless connection to your processing or packaging lines. Third-party solutions for robotics or AGVs can be integrated to create the best handling system.

Learn moreViscon provides a diverse range of handling and transportation systems in processes like conveying, (de)stacking, (un)loading, box folding, crate unfolding, sorting, order picking, storage and palletizing.

This next generation of software intelligently integrates all automation functions. It offers product traceability and unlocks performance optimization. This allows our customers to get the most out of their production facility. The software incorporates the functionality of MES, WCS and WMS and can be integrated with existing systems such as ERP.

Learn moreWe integrate all equipment and software and hand over a seamlessly working process for a new or existing production line. A flexible approach is possible thanks to our in-house engineering, production and software capabilities.

Our palletizers will be based on the requirements and needs of your production location, for example in terms of capacity and available physical space on the work floor. Our palletizers and depalletizers are applicable for a wide reange of products and pallet types to be stacked or destacked. In addition, we supply all necessary equipment, such as conveyor belts, pallet tracks and fencing.

Viscon provides belt, roller and chain conveyors for product carriers such as pallets, boxes and crates. Available in different materials such as aluminum, steel and stainless steel, as well as curved and spiral conveyors.

Examples of Viscon’s robotic applications include: pick & place systems, palletization and depalletization of various products, order picking, case packing, loading and unloading, etc.

We plug the hardware in our in-house developed intelligent software that will have the same base and structure as the rest of our system solutions. This means we can deliver a fully integrated solution, all controlled by one software system.

Designing an optimal crate flow is key when crates need to be cleaned and handled by the hundreds and thousands per hour. At Viscon, we create fully automated cleaning solutions that let you focus on your core business.

Learn moreBased on your operations, facility and preferences our engineers design the optimal logistics flow. We use standard components, which can easily be modified and scaled up. We can offer this flexibility thanks to our in-house engineering, production and software capabilities.

We take care of the total project management from concept to commissioning. It’s about the integration of equipment into a complete system. Powered by software that creates higher efficiency and performance of your facility.

With more than 60 years of experience and a strong focus on innovation, we provide customized solutions that perfectly match your specific needs.

Streamline your logistics processes and reduce operational costs without compromising on quality.

We understand that every business is unique. That’s why we offer flexible solutions tailored to your requirements and goals.