This page is being translated by Google Translate

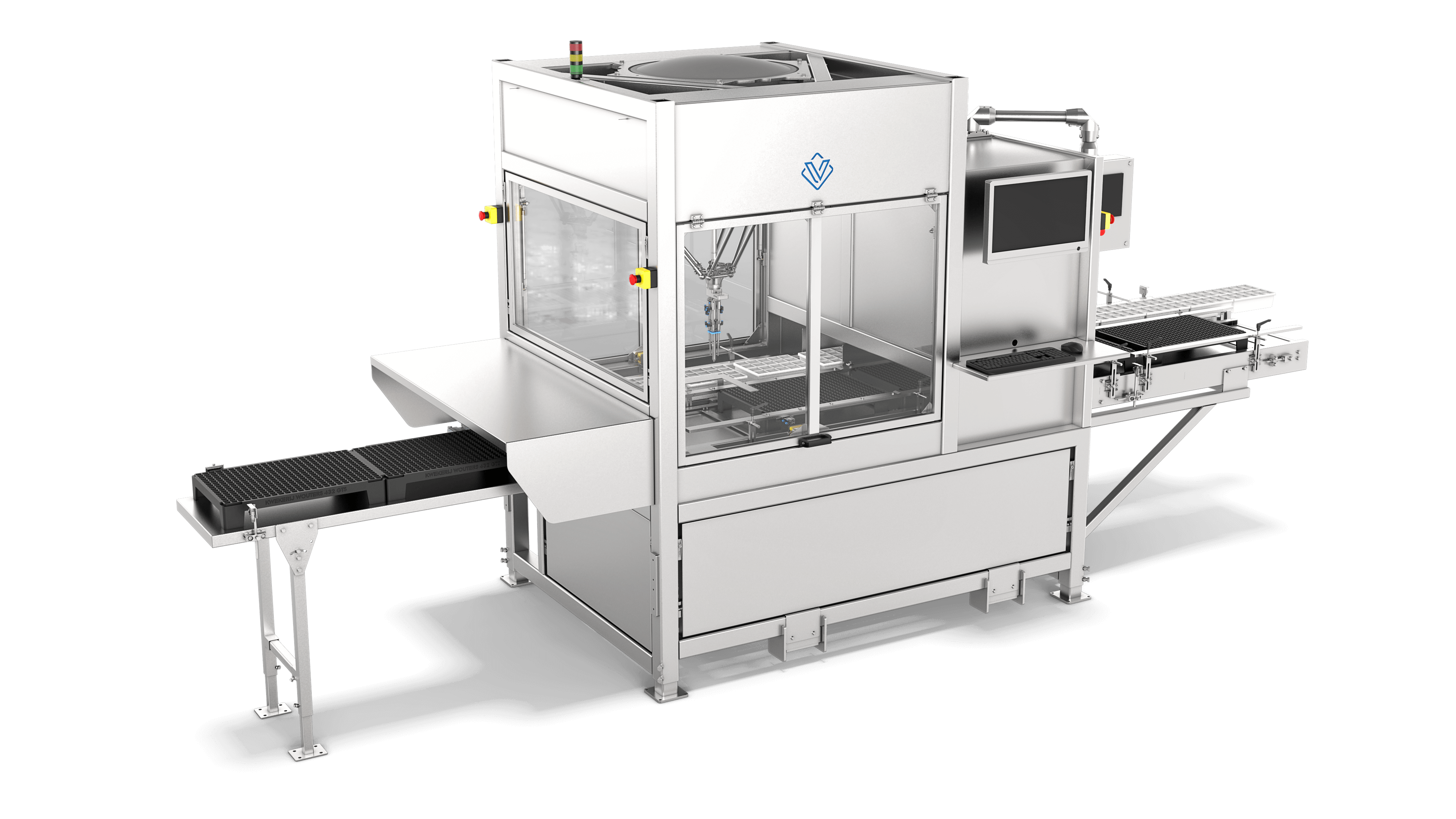

Viscon has introduced a new robotic gap filling solution for plant growers using advanced Delta robotic technology. This machine ensures 100% filled plant trays by eliminating inefficiencies in the transplanting process where missing plants can occur.

The high speed, precision, and user-friendliness make it a valuable investment for growers looking to optimize their production lines while reducing labor costs. This robot filler provides an efficient and reliable solution for automatically filling in missing plants, leading to higher productivity, improved quality, and reduced losses.