This page is being translated by Google Translate

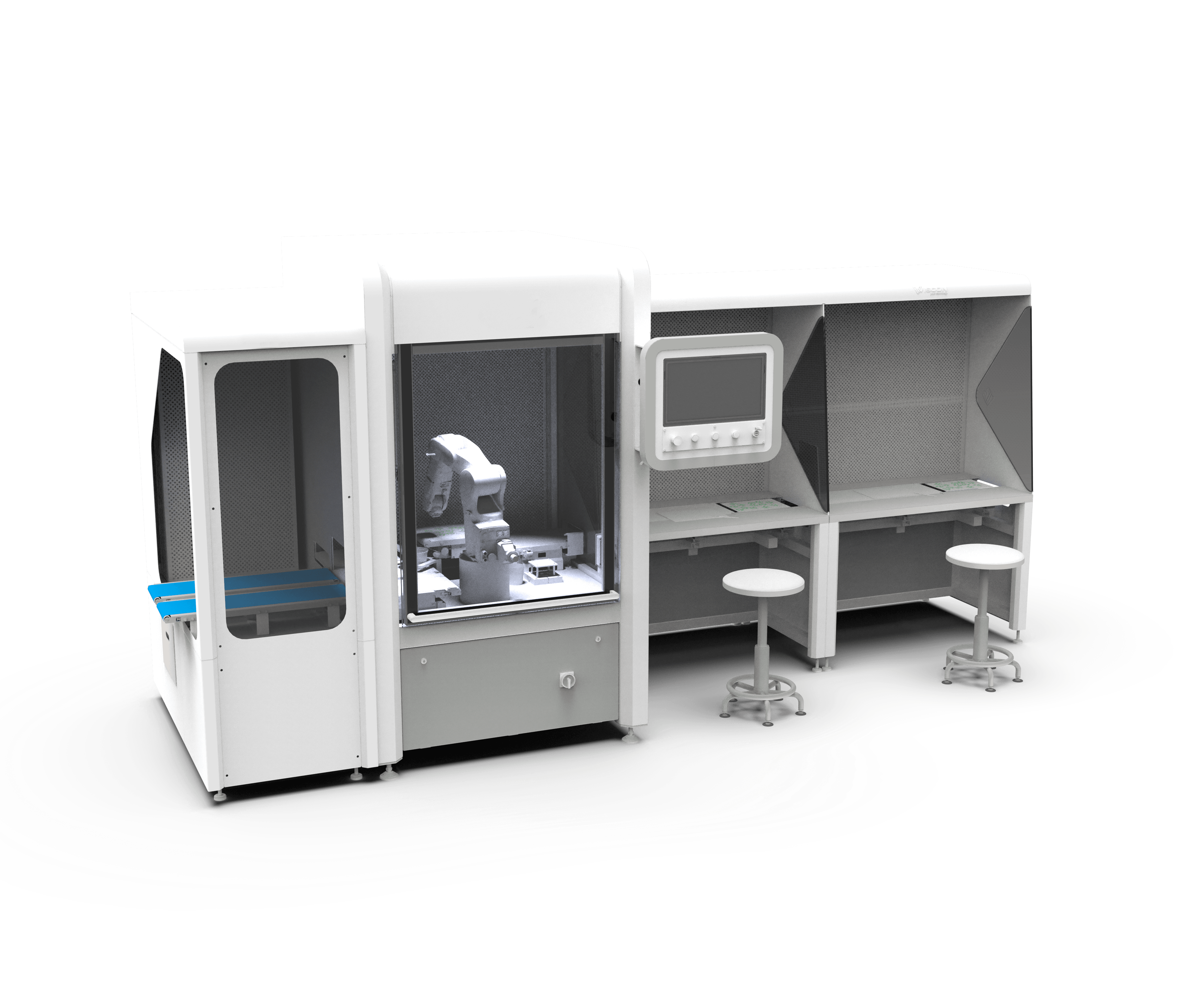

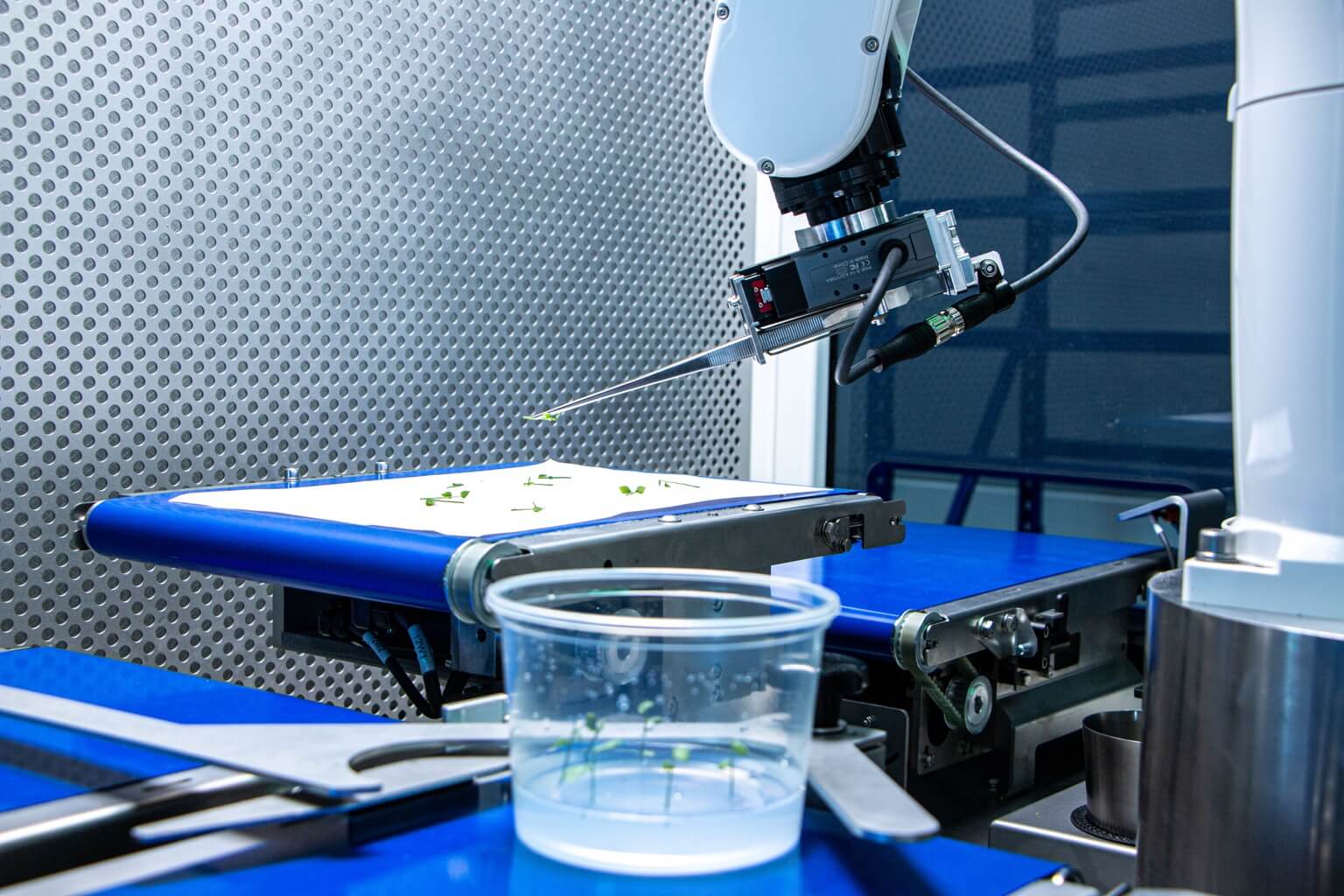

With its cutting-edge technology, this innovative Tissue Culture Planter elevates your TC production to new levels of excellence. By automating the transplanting process, it optimizes production capacity and boosts operational efficiency, while also ensuring uniform growth, sterility assurance, and enhanced traceability through advanced software integration. Combined, these factors lead to exceptional plant quality!

Viscon Plant Technology and ISO collaborate to revolutionize plant tissue culture production! The technologically advanced partners unveil their cutting-edge Tissue Culture Planter, optimizing and automating the labor-intensive process of explant transfer during multiplication!

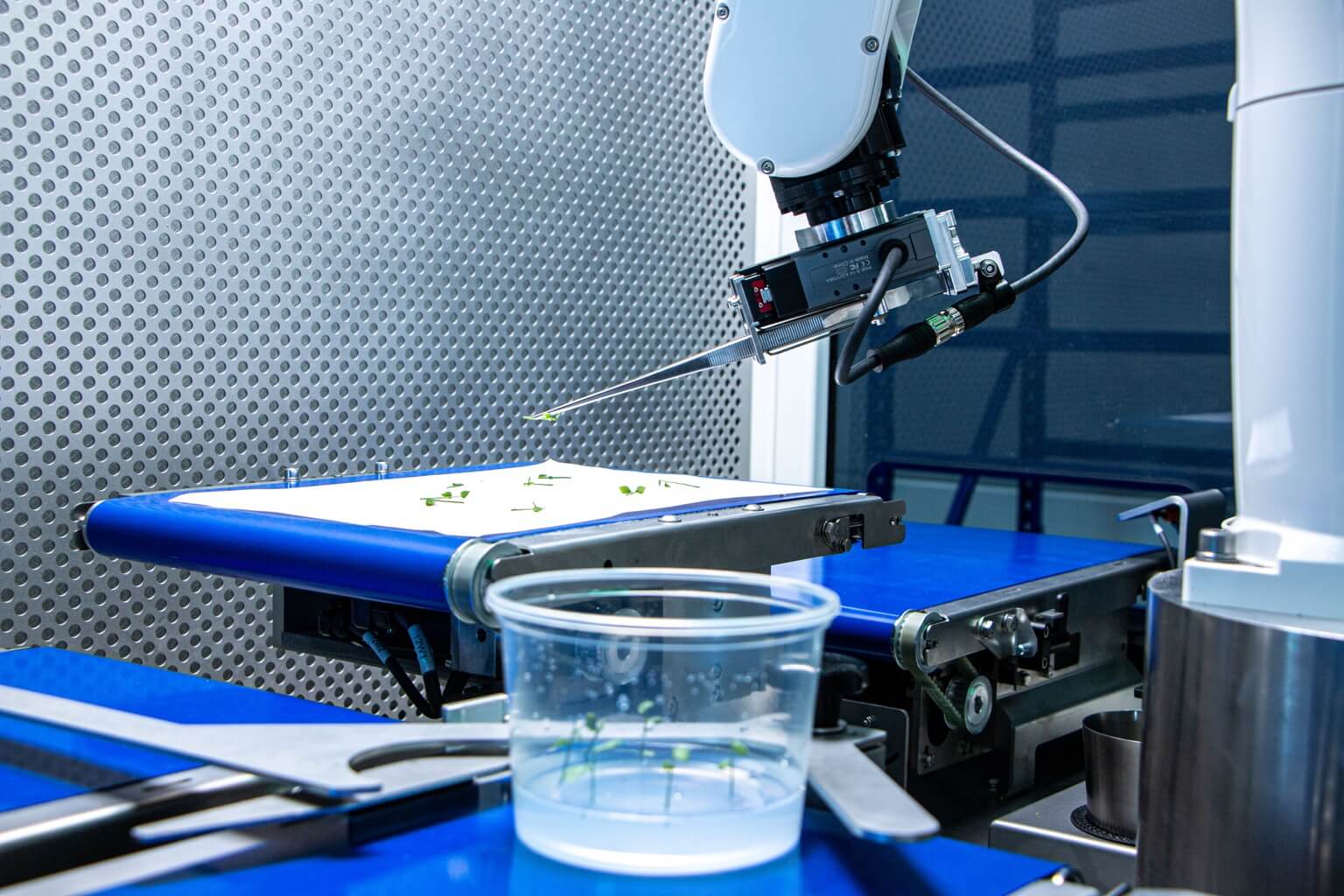

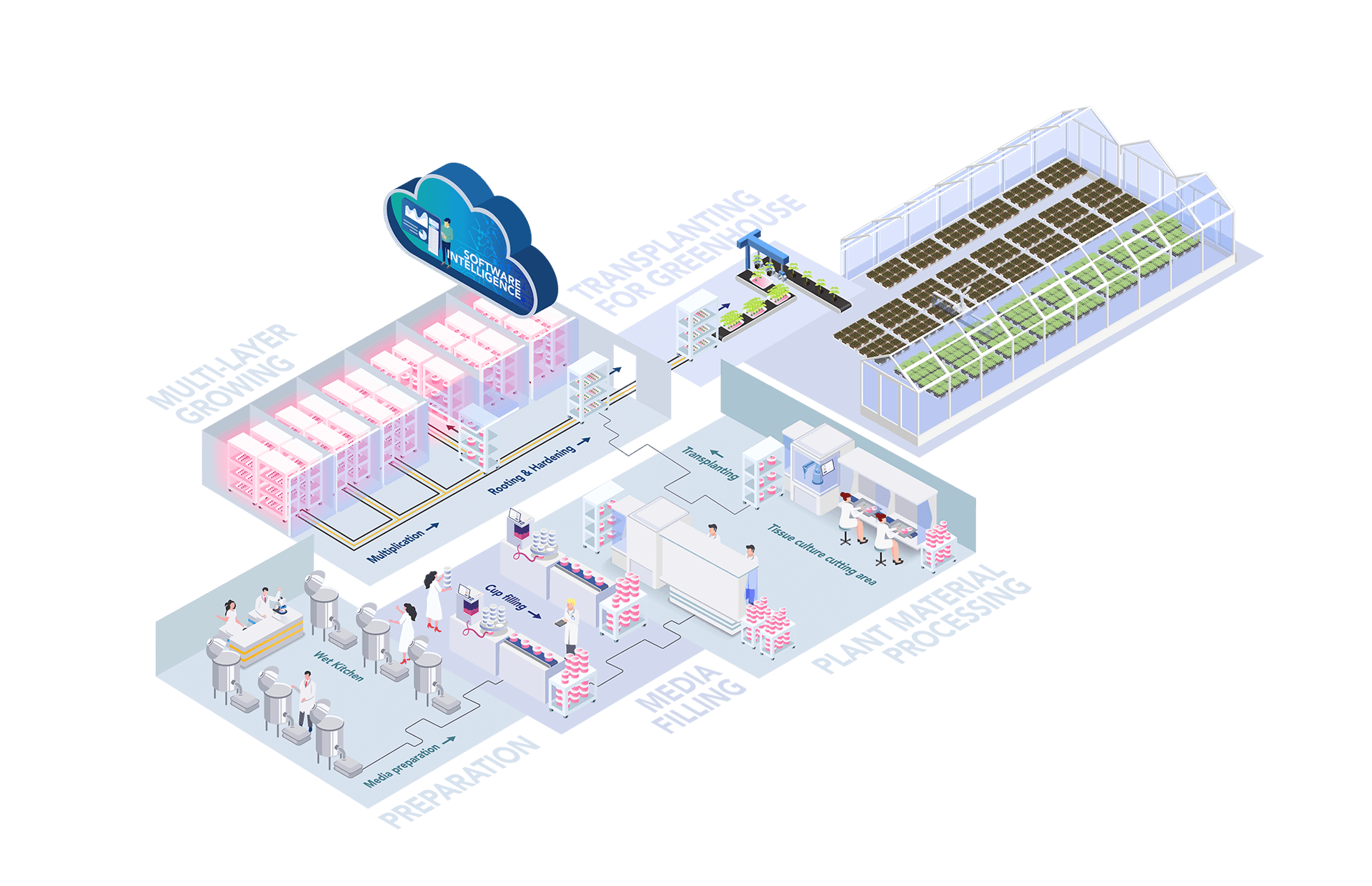

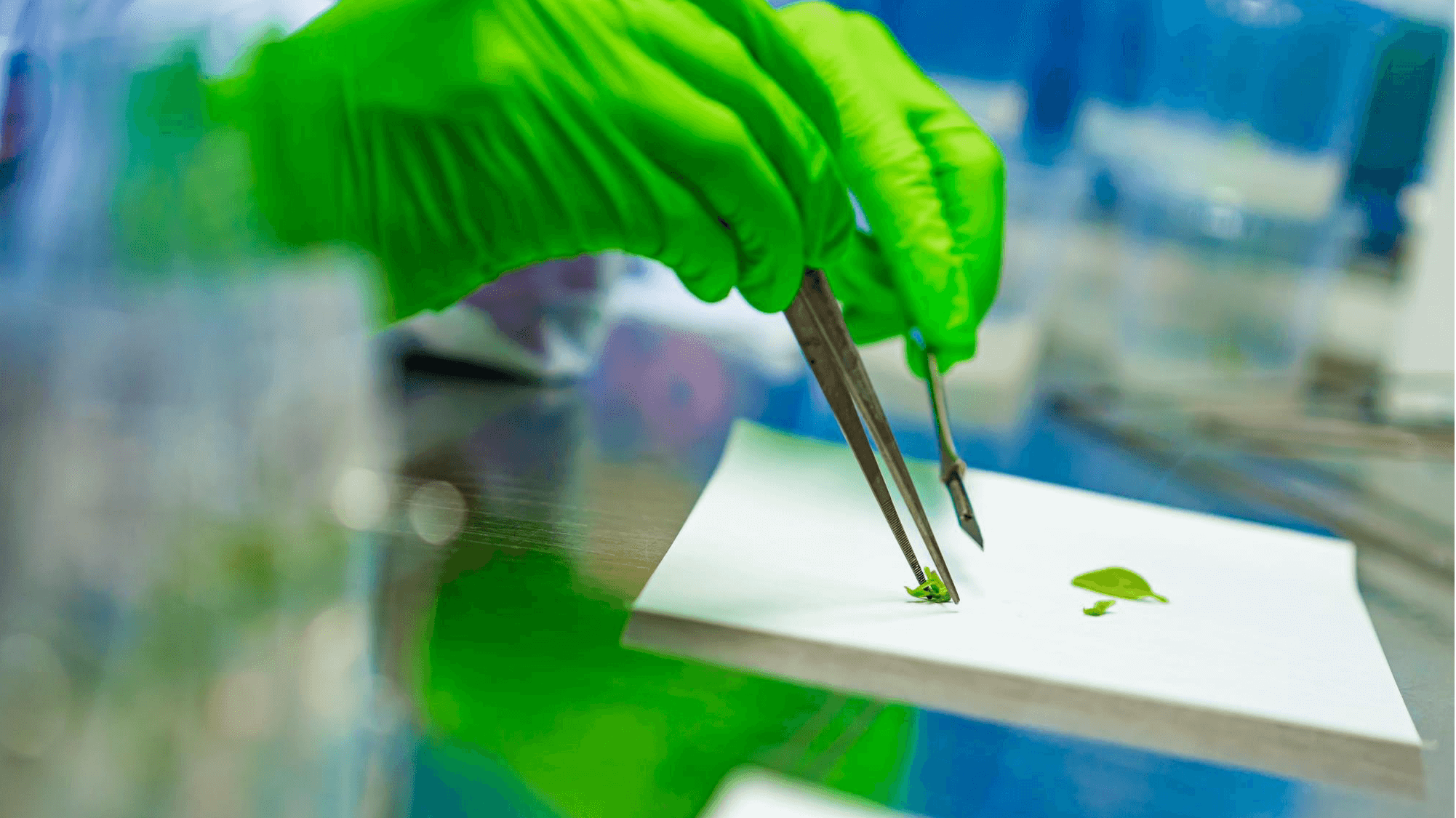

Propagation through tissue culture is a delicate and labor-intensive process with workers having to handle multiple steps in cutting and transplanting the plants manually. Automating the transplanting process improves operational efficiency by allowing workers to focus solely on the cutting part increasing overall speed and productivity.

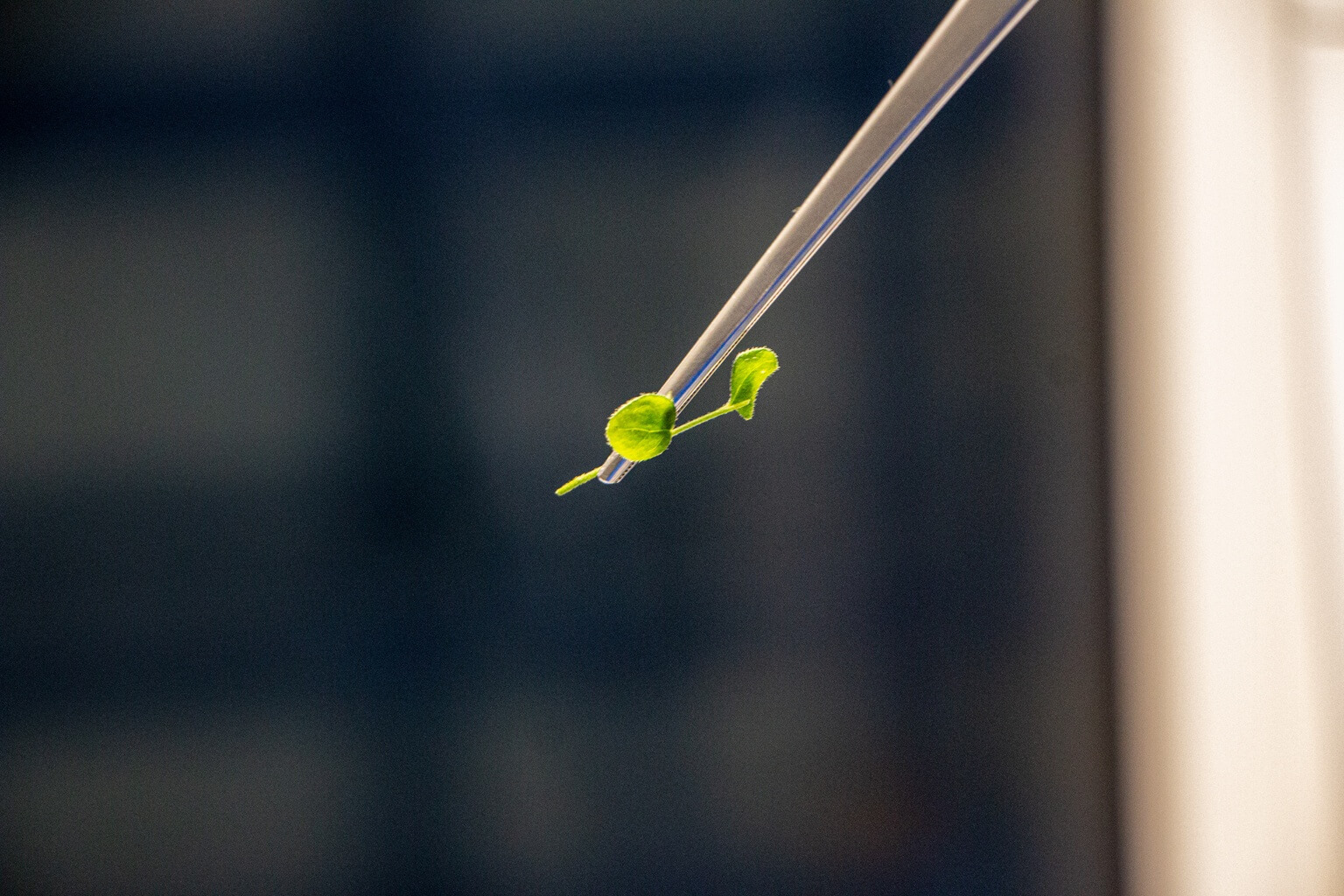

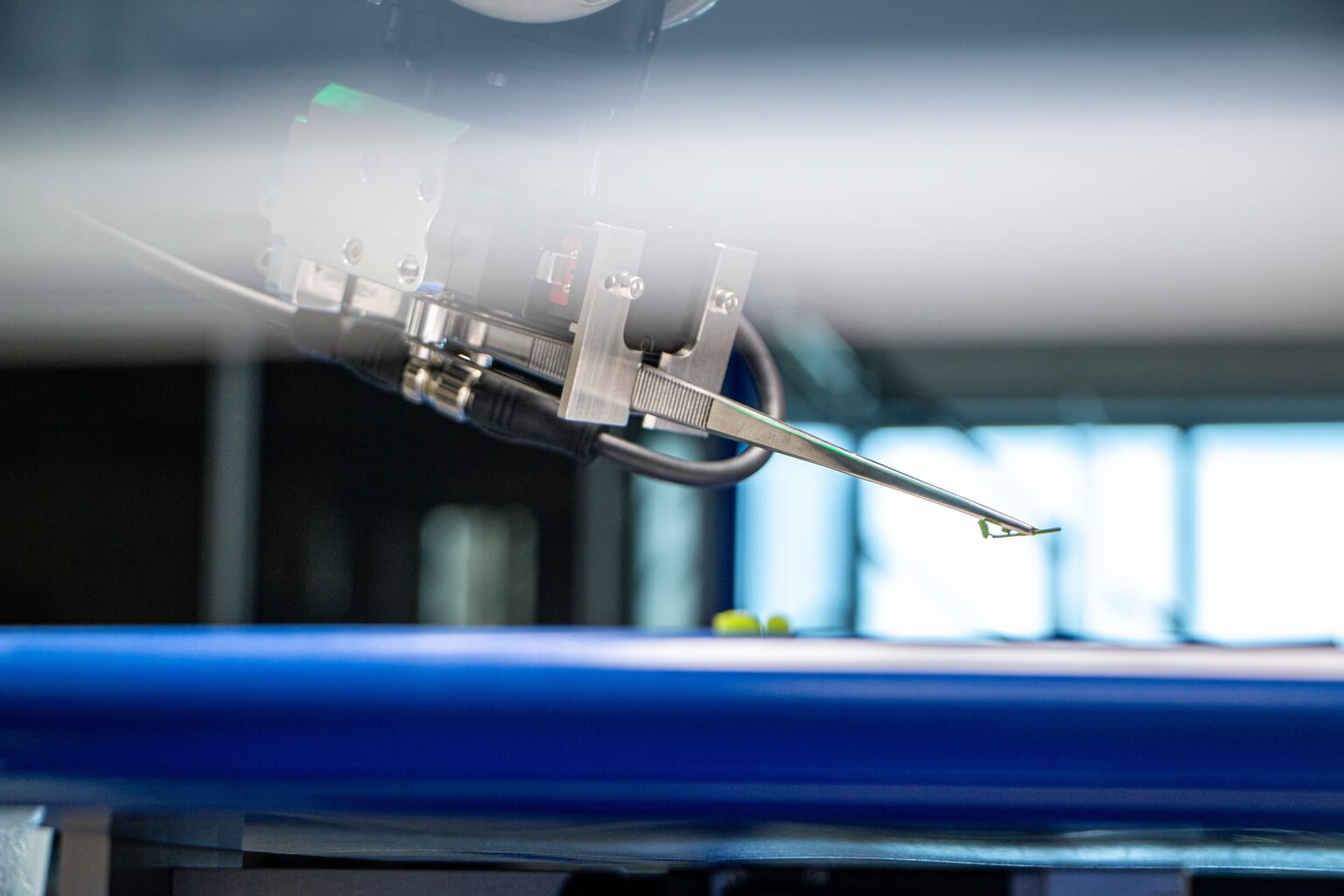

By automating the transplanting process, individual plants are carefully planted at a predetermined position and depth into the agar, resulting in improved uniformity. Advanced gripper technology focused on precision ensures minimal physical damage to plants, while automation allows workers to fully concentrate on the cutting. Combined these factors ultimately enhance plant quality.

Ensuring sterility is essential in TC laboratory processes and was prioritized during the development of this transplanting machine. The technology features in-place tool sterilization, ensuring that the gripping tools are automatically sterilized between batches. Automating the transplanting process also reduces human handling, thereby effectively minimizing the risk of contamination caused by manual plant handling.

The traceability and control software provided by Viscon enhances operational efficiency and quality control. Using barcoding technology, tracking and tracing plants in cups is automated, ensuring accurate monitoring and traceability to the original plant material. Data capturing, including production numbers, multiplication rates, material losses and location status allows monitoring of plant production and can be integrated with other software systems.

The new Tissue Culture Planter will be integrated into the tissue culture platform offered by Viscon, where a complete solution for TC laboratories is provided, including facility design, climate-controlled multilayer propagation rooms, labor-saving automation, growing consumables, software, and in-house training.

In the fully controlled growing chamber the ViTray helps you root and harden your plants. The ViTrays hold substrate in which the plants can grow roots. The plants can harden in the ViTray in the cell as well, via the Viscon micro perforation. Viscon supplies both the automation for the filling of the trays and the complete growing chamber.

Read more

By automating the transplanting process, it optimizes production capacity and boosts operational efficiency, while also ensuring uniform growth, sterility assurance, and enhanced traceability through advanced software integration. Combined, these factors lead to exceptional plant quality!

Read more

Both cups and trays can be filled with agar in the media preparation area. Viscon supplies unique media preparators with an unprecedented capacity. These media preparators connect to the filling lines to automate the filling process. Nutrition can be connected as well. Both filling and seeding can be automated, for processes with soil mixes.

Read more

When the plants are rooted and hardened they can be automatically transplanted. Viscon Plant Technology supplies a transplanter for a fully automated process.

Read more

We offer tracking & tracing software to supply all your products with the correct information down the supply chain. Plant tissue culture software can be used as a planning and calculation tool for data & stock management and barcode labeling.

In the laboratory Viscon provides everything required for a smooth setup to process your plants. Laminar flow cabinets, equipment for the staff, trolleys for transport and all disposables. For a Viscon process a sealing machine is available as well.

In any kind of laboratory everything starts with a clean operation. Viscon supplies everything you need to clean and sterilize all materials in your lab.

Read more