This page is being translated by Google Translate

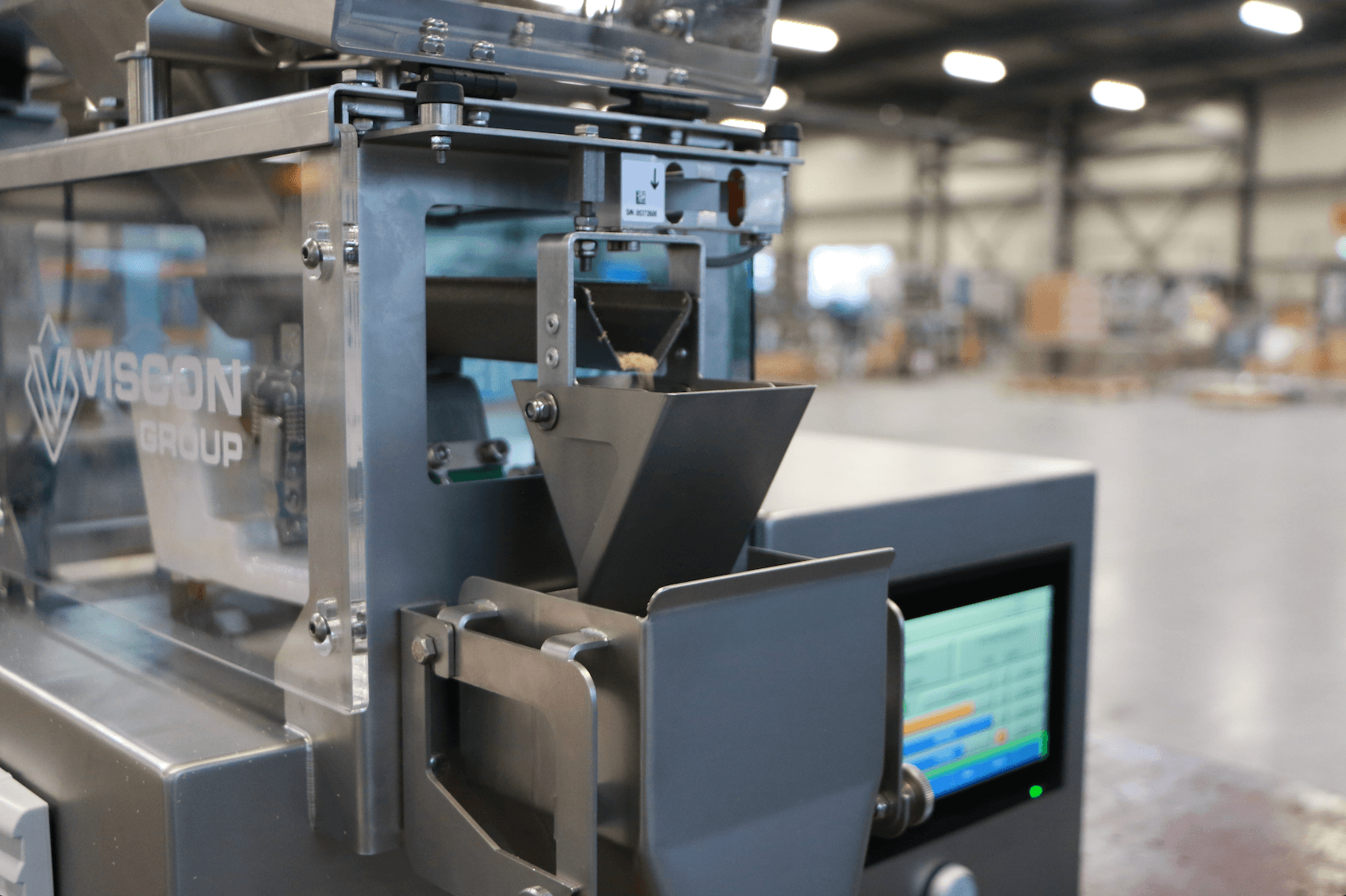

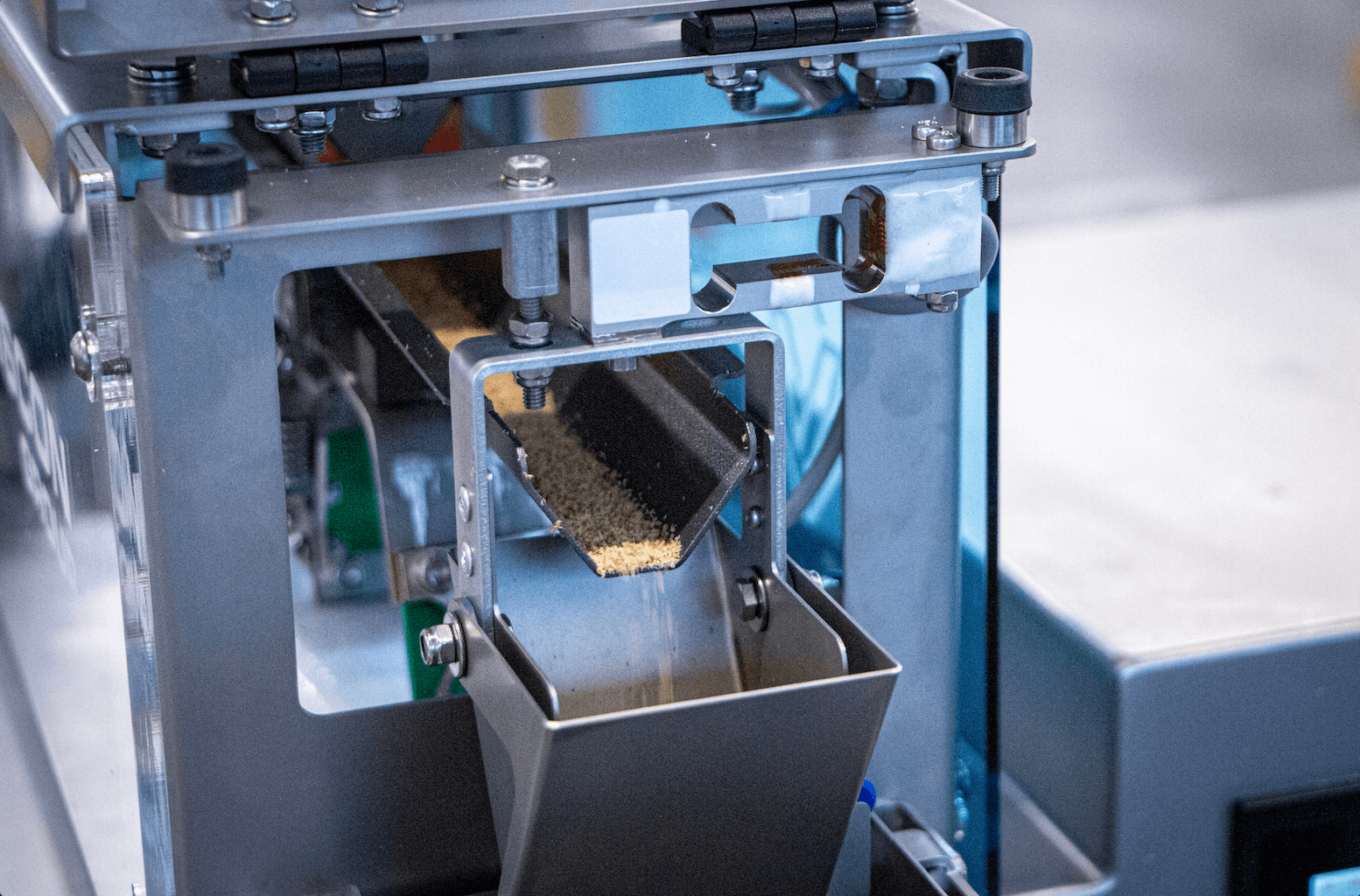

Upgrade your farm operations with our automated dosing system for neonates. The entodose has been specifically designed for the delicate handling of neonates, with an optimized combination of low dosing weight, high accuracy and high speed.

The characteristics of neonates and the needs of farmers have been analyzed to influence our design choices. No matter the size of your farm, we have the right solution for you.

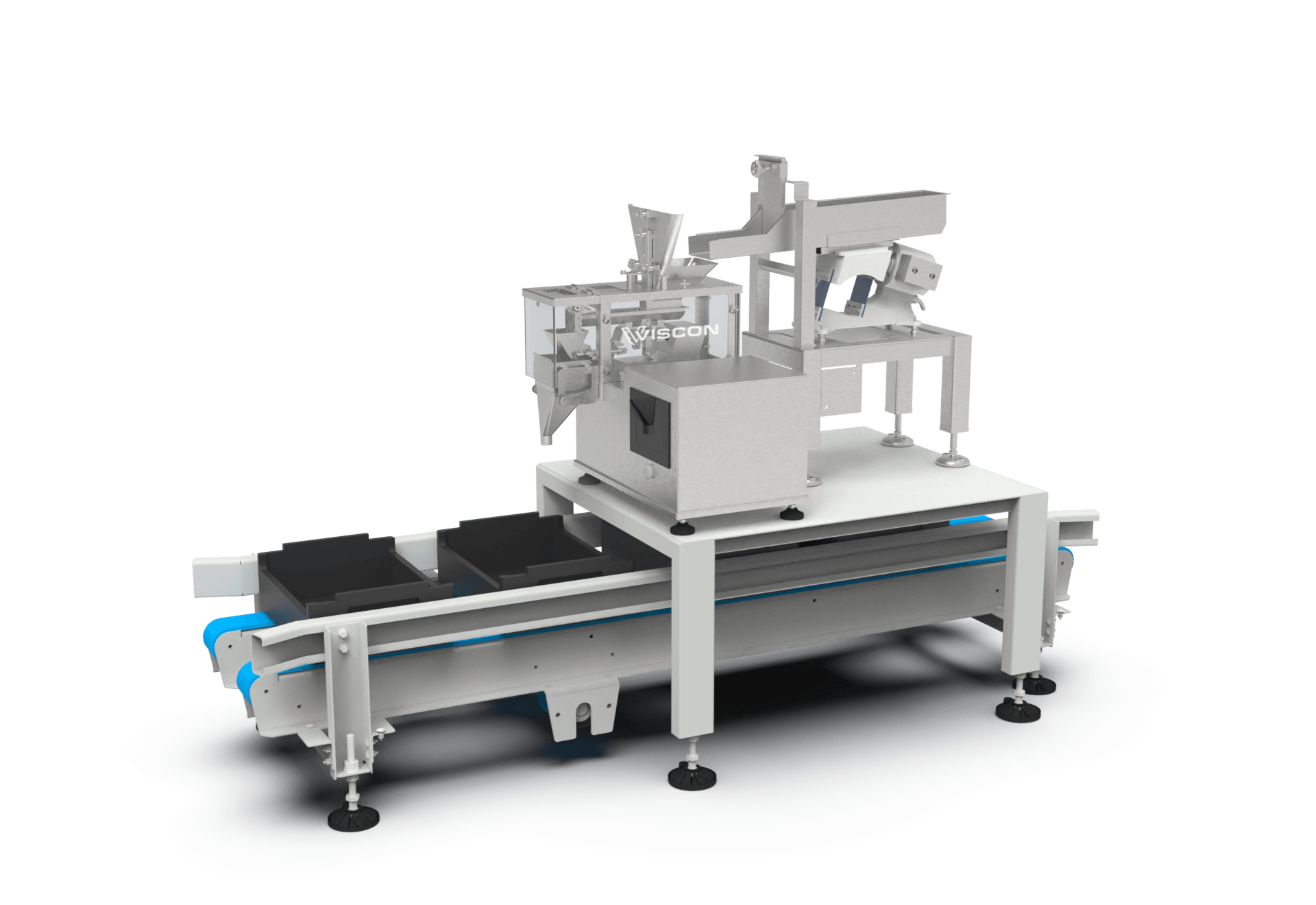

The Entodose can be delivered and installed as a fully automated dosing process. Viscon conveyors, a frame and other hardware and software are connected to automate the nursery phase.

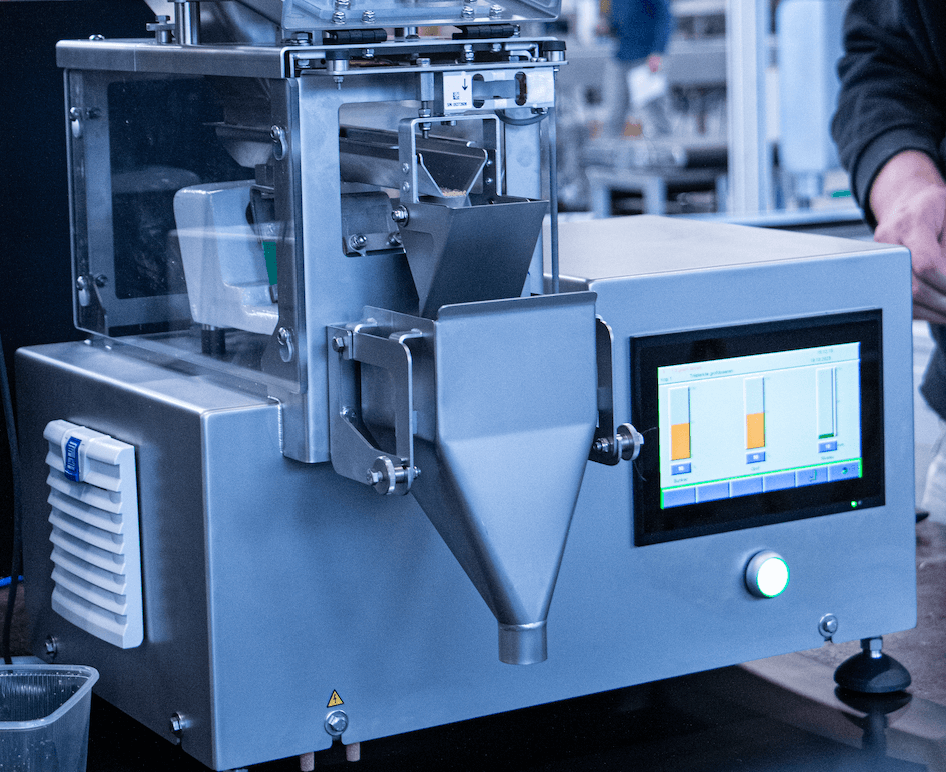

Control the entodose via touch screen or connect the system to the operator room. The integrated software allows you to define the optimal settings to fit your specific needs regarding precision, speed and weight.

The Entodose is able to reach a capacity of 450 crates per hour when dosing several grams per instance. If needed, we can upgrade the machine with additional dosing heads to further increase performance.

Viscon’s insect farming technology and software solutions provide the backbone for an automated insect factory. Our decades’ worth of experience in factory intralogistics automation ensures an optimized process tailored to the needs of farming black soldier flies (BSF) and mealworms.

Viscon takes pride in jointly developing the logistical process with our customers. Based on in-house engineering, production and software development, Viscon incorporates all our customers’ needs within our scope in an optimized insect farming design. During this process, we also establish a seamless connection with any third-party equipment, like insect feed technologies and climate control (HVAC).