This page is being translated by Google Translate

Whether experienced with tissue culture or new to the plant tissue culture world, we provide everything to build a complete cutting-edge tissue culture laboratory. We provide a turnkey solution from the design of your facility to climate-controlled multilayer propagation rooms, labor-saving automation, worker equipment, growing consumables and in-house training.

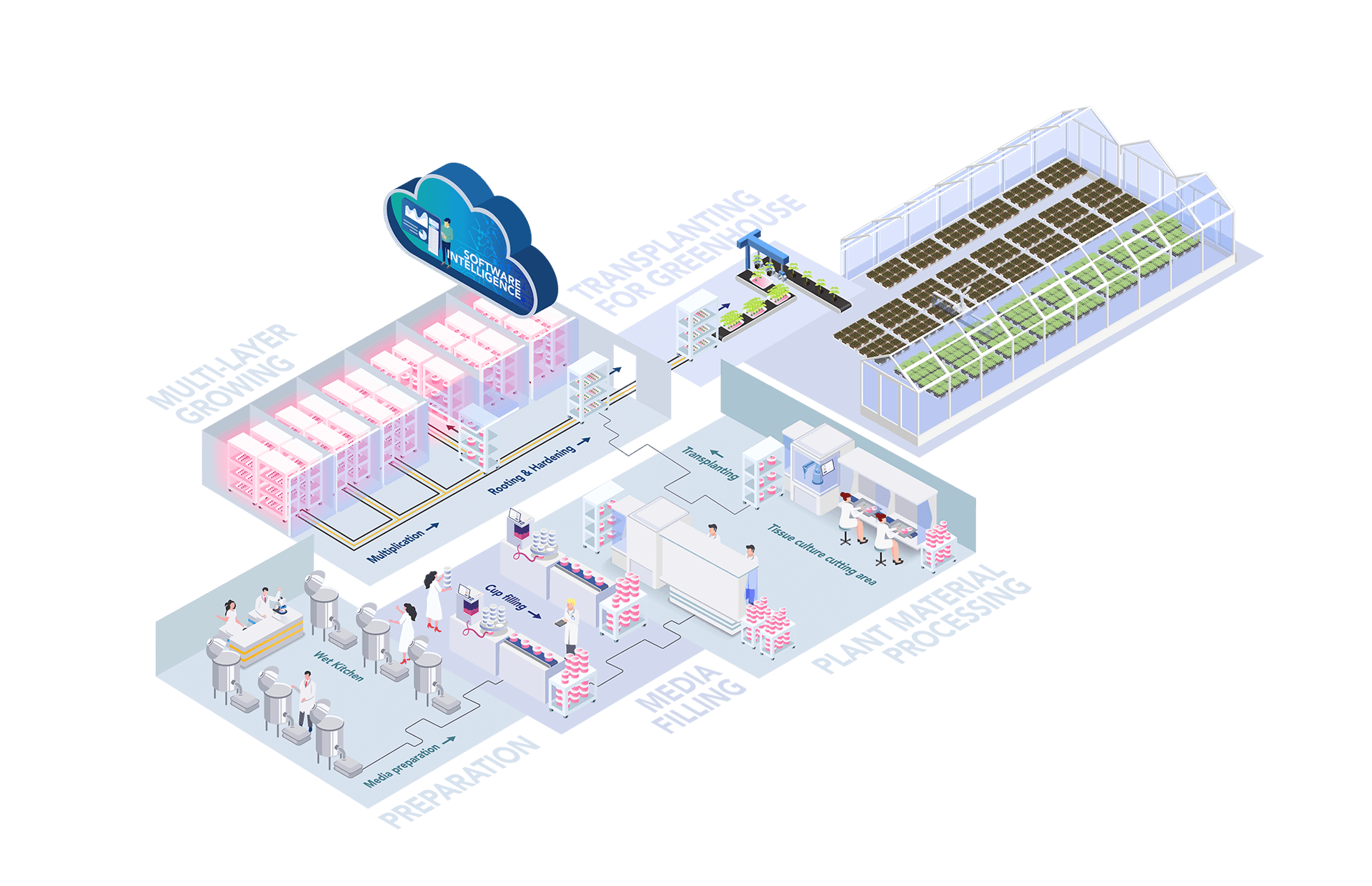

We design a complete layout for your plant factory. We have extensive experience creating the most efficient tissue culture laboratories. Including areas such as the preparation area, media filling and seeding area, plant material process area, and multi-layer rooting and hardening area.

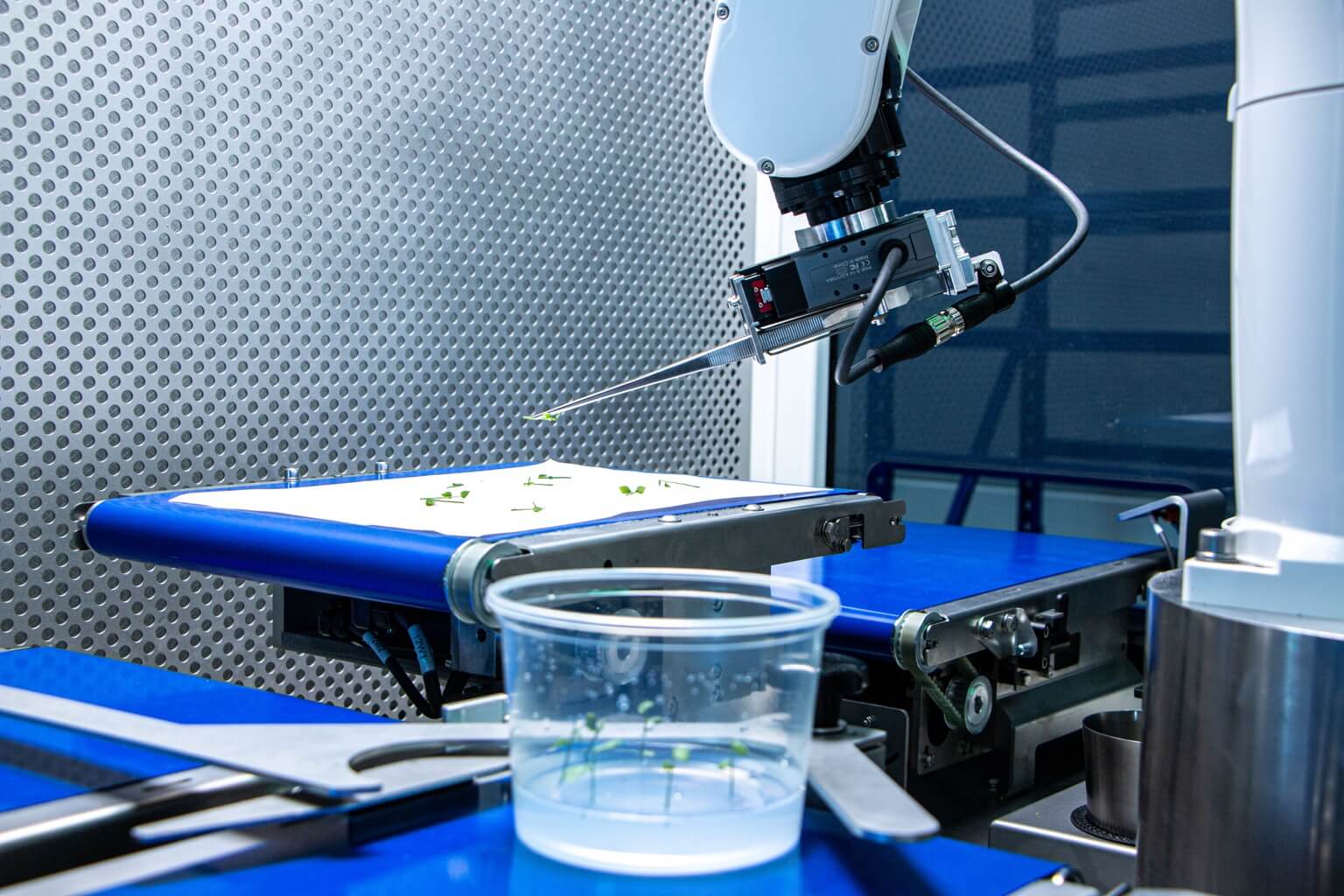

By automating the transplanting process, it optimizes production capacity and boosts operational efficiency, while also ensuring uniform growth, sterility assurance, and enhanced traceability through advanced software integration. Combined, these factors lead to exceptional plant quality!

Learn moreThe ViTrolley is a LED trolley with a unique design and is fully compatible with the ViCabin. The trolley with diffused LED panels creates the ideal light spectrum, climate and day-night rhythm for your plants.

Learn more

The ViTray provides a revolutionary method for the rooting of plants. Because of the unique permeable foil rooting and hardening of the plants occur simultaneously, saving time and space. The ViTray also acts as an excellent shipping package.

We offer automated production lines and automate all logistic processes in the lab. Viscon automation saves time and significantly reduces contamination risks, labor costs and mistakes.

Learn moreBecause in different parts of the world different certifications are required, we work with partners all over the world. This ensures the laboratory equipment complies with your national laws and regulations.

We offer fully automated production lines with filling, seeding, (de)stacking, transplanting, watering and vision grading machines. Our logistic handling systems, potted plant transportation, soil handling, irrigation systems and track & trace delivery systems create the optimal flow in your nursery.

Learn moreThe lab complies with all phytosanitary requirements thanks to sterile laboratory conditions. It is equipped with areas for preparing media, cutting plants and has a controlled environment multi-layer growing setup.

Learn moreViscon Factory Intelligence software provides you with the most advanced software. Using the software all information from production to the customer is available on your multiplication cups, trays, and boxes.

With this knowledge built up over the years, we can advise you on media, lightning, climate, tissue culture production and automation solutions. We can design each protocol you might need and assist you with in-house training and R&D support.

Learn moreAs a research and innovation-driven company, plant tissue culture is embedded in our DNA. We’ve been developing solutions for this sector for over a decade. We differentiate ourselves by our horticultural know-how, automation expertise and unique multi-layer cultivation system.

Using our approach, you can increase the rooting rate and uniformity of the plants. We do this by skipping the in-vitro rooting step using the Vitray; a “Greenhouse in a box” logistic solution for the protection of young plants. Our multi-layer indoor rooting & hardening setup creates a sterile and fully controlled production environment. In addition, we provide custom-made automation for all labor-intensive production processes.

In the fully controlled growing chamber the ViTray helps you root and harden your plants. The ViTrays hold substrate in which the plants can grow roots. The plants can harden in the ViTray in the cell as well, via the Viscon micro perforation. Viscon supplies both the automation for the filling of the trays and the complete growing chamber.

Read more

By automating the transplanting process, it optimizes production capacity and boosts operational efficiency, while also ensuring uniform growth, sterility assurance, and enhanced traceability through advanced software integration. Combined, these factors lead to exceptional plant quality!

Read more

Both cups and trays can be filled with agar in the media preparation area. Viscon supplies unique media preparators with an unprecedented capacity. These media preparators connect to the filling lines to automate the filling process. Nutrition can be connected as well. Both filling and seeding can be automated, for processes with soil mixes.

Read more

When the plants are rooted and hardened they can be automatically transplanted. Viscon Plant Technology supplies a transplanter for a fully automated process.

Read more

We offer tracking & tracing software to supply all your products with the correct information down the supply chain. Plant tissue culture software can be used as a planning and calculation tool for data & stock management and barcode labeling.

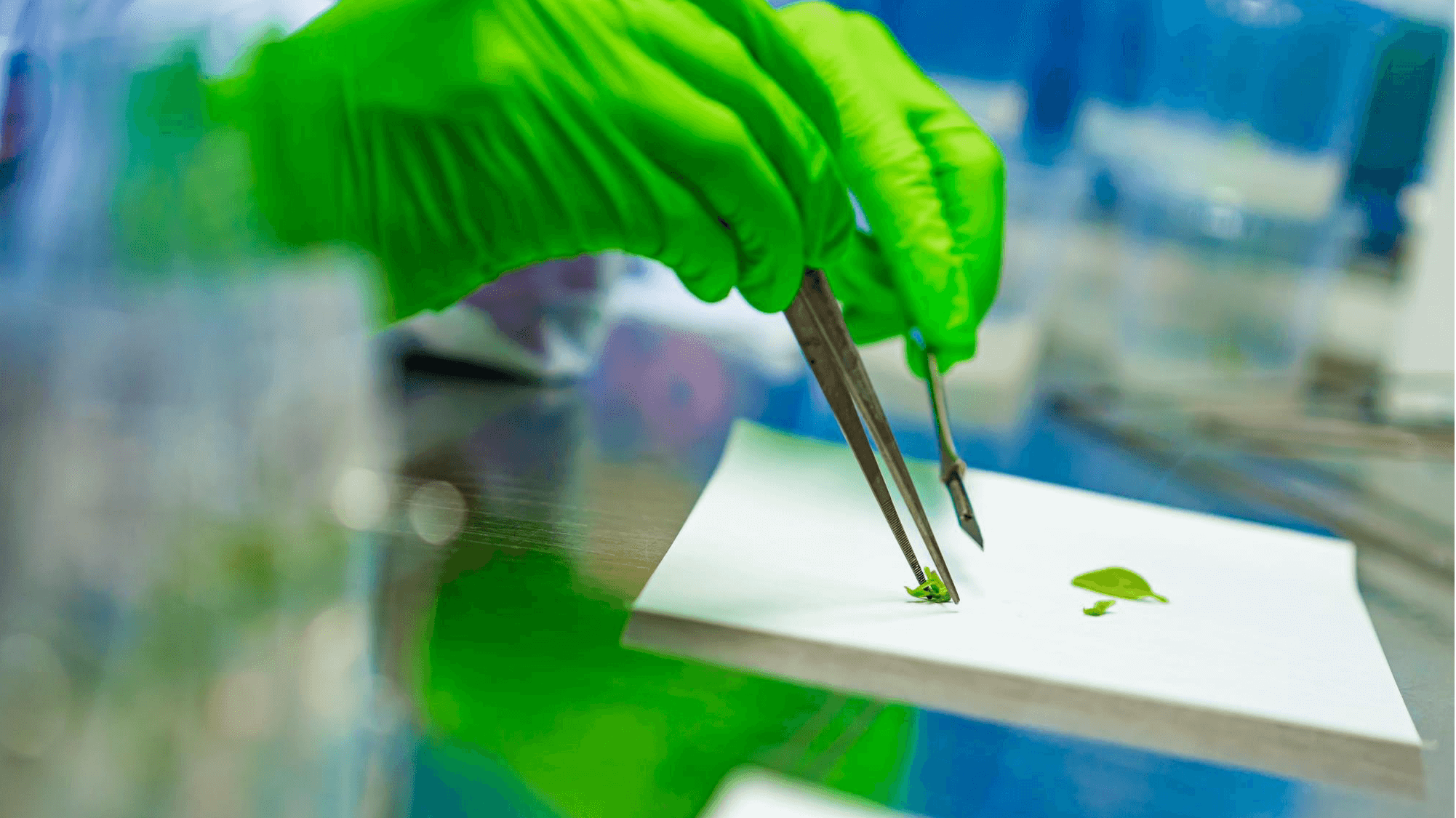

In the laboratory Viscon provides everything required for a smooth setup to process your plants. Laminar flow cabinets, equipment for the staff, trolleys for transport and all disposables. For a Viscon process a sealing machine is available as well.

In any kind of laboratory everything starts with a clean operation. Viscon supplies everything you need to clean and sterilize all materials in your lab.

Read more