Viscon and ISO collaborate to unlock Tissue Culture automation

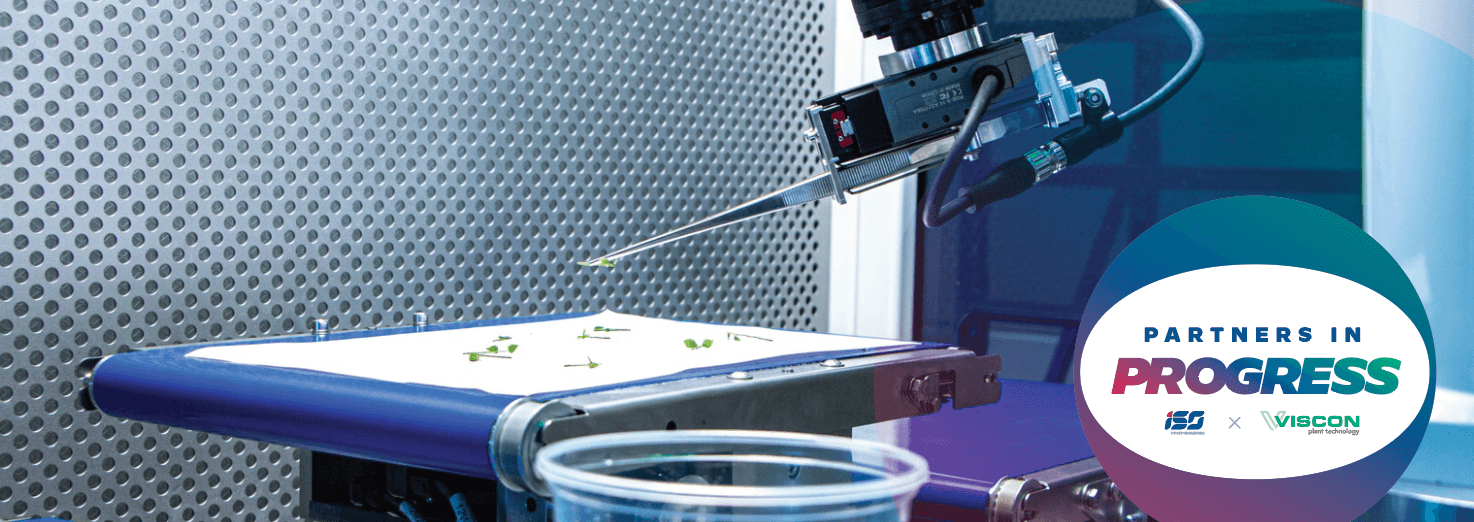

GreenTech Amsterdam, June 13, 2023 – Viscon Plant Technology and ISO have teamed up to automate the process of plant tissue culture production. During GreenTech, the technologically advanced partners unveil their cutting-edge Tissue Culture Planter that will revolutionize the way young plant production is carried out through tissue culture.

The current demand for Tissue Culture (TC) plants significantly exceeds the supply, due to the labour-intensive nature of this cultivation process. The two companies, despite being competitors in other fields, decided to join forces to accelerate automation in TC labs. Through this collaboration, the labour-intensive process of explant transfer during multiplication can be optimized and automated.

The increasing global demand for tissue culture plants is driven by the reliability of the material. However, the lack of automation currently obstructs the industry from meeting the required demands. “This innovative technology represents a crucial first step in improving the availability of tissue culture material, both in terms of quantity and proximity. Due to the labor-intensive production, the plants are often only produced in locations where labor is affordable and available,” said Charlotte Langerak-Visser (CEO of Viscon Group) and Wim van der Meyden (CEO of ISO). “The combined strengths of our two companies aim to accelerate the adoption of this technology in the market, meeting current customer needs and opening new possibilities in this exciting field!”

ISO, innovator in horticultural automation solutions, brings its expertise and innovative technology for plant cutting transplanting to the partnership. With an extensive R&D team, ISO further built on their existing technology extending its application to the laboratory environment. Viscon Plant Technology is a trusted partner with a broad network in the field of young plant production, as well as expert knowledge of TC production. Their in-house plant science team offers a high level of expertise to co-create an excellent automated process.

The new Tissue Culture Planter will be integrated into the tissue culture platform offered by Viscon, where a complete solution for TC laboratories is provided, including facility design, climate-controlled multilayer propagation rooms, labor-saving automation, growing consumables, software, and in-house training. At GreenTech, the technologically advanced partners will showcase their high-tech Tissue Culture Planter, offering significant benefits:

Increasing Production Capacity

Propagation through tissue culture is a delicate and labor-intensive process with workers having to handle multiple steps in cutting and transplanting the plants manually. Automating the transplanting process improves operational efficiency by allowing workers to focus solely on the cutting part increasing overall speed and productivity.

Guarantees Uniform Growth

By automating the transplanting process, individual plants are carefully planted at a predetermined position and depth into the agar, resulting in improved uniformity. Advanced gripper technology focused on precision ensures minimal physical damage to plants, while automation allows workers to fully concentrate on the cutting. Combined these factors ultimately enhance plant quality.

Safeguarding Sterility

Ensuring sterility is essential in TC laboratory processes and was prioritized during the development of this transplanting machine. The technology features in-place tool sterilization, ensuring that the gripping tools are automatically sterilized between batches. Automating the transplanting process also reduces human handling, thereby effectively minimizing the risk of contamination caused by manual plant handling.

Enhancing Traceability software

The traceability and control software provided by Viscon enhances operational efficiency and quality control. Using barcoding technology, tracking and tracing plants in cups is automated, ensuring accurate monitoring and traceability to the original plant material. Data capturing, including production numbers, multiplication rates, material losses and location status allows monitoring of plant production and can be integrated with other software systems.

nl

nl en

en